9000+ Cashless

Network Garages

96% Claim

Settlement (FY23-24)

24*7 Claims

Support

Click here for new car

I agree to the Terms & Conditions

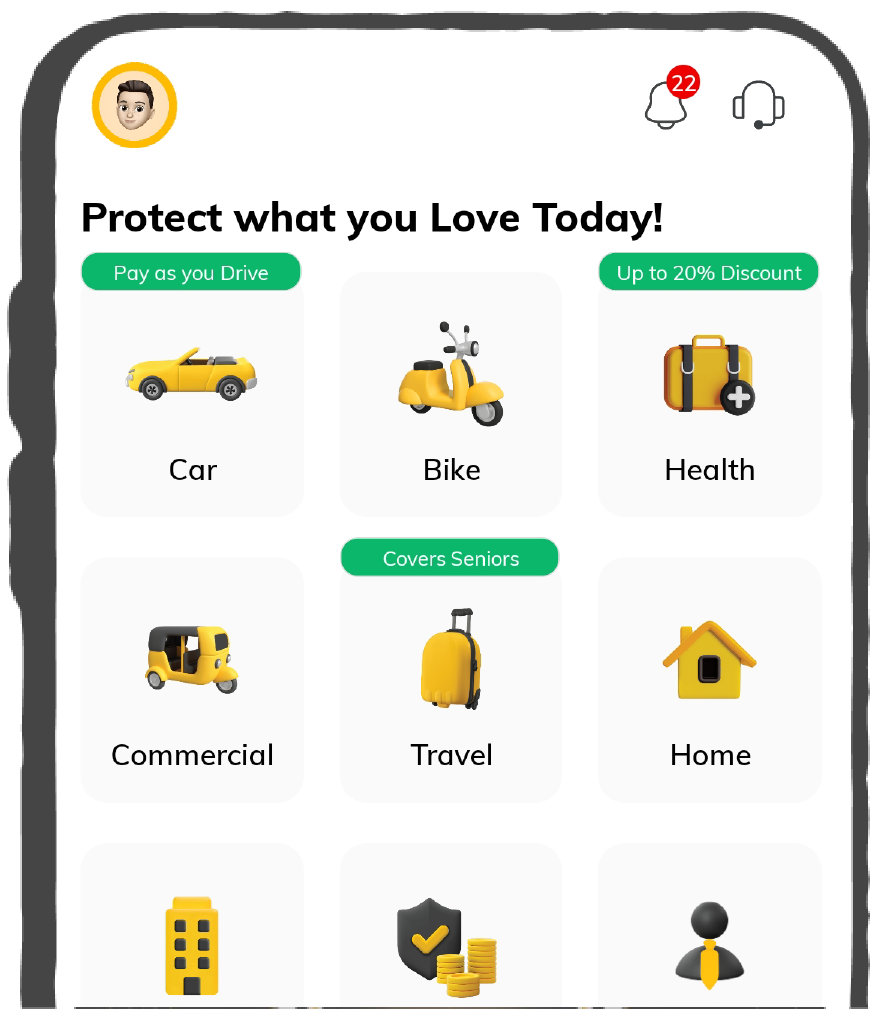

General

General Products

Simple & Transparent! Policies that match all your insurance needs.

37K+ Reviews

7K+ Reviews

Scan to download

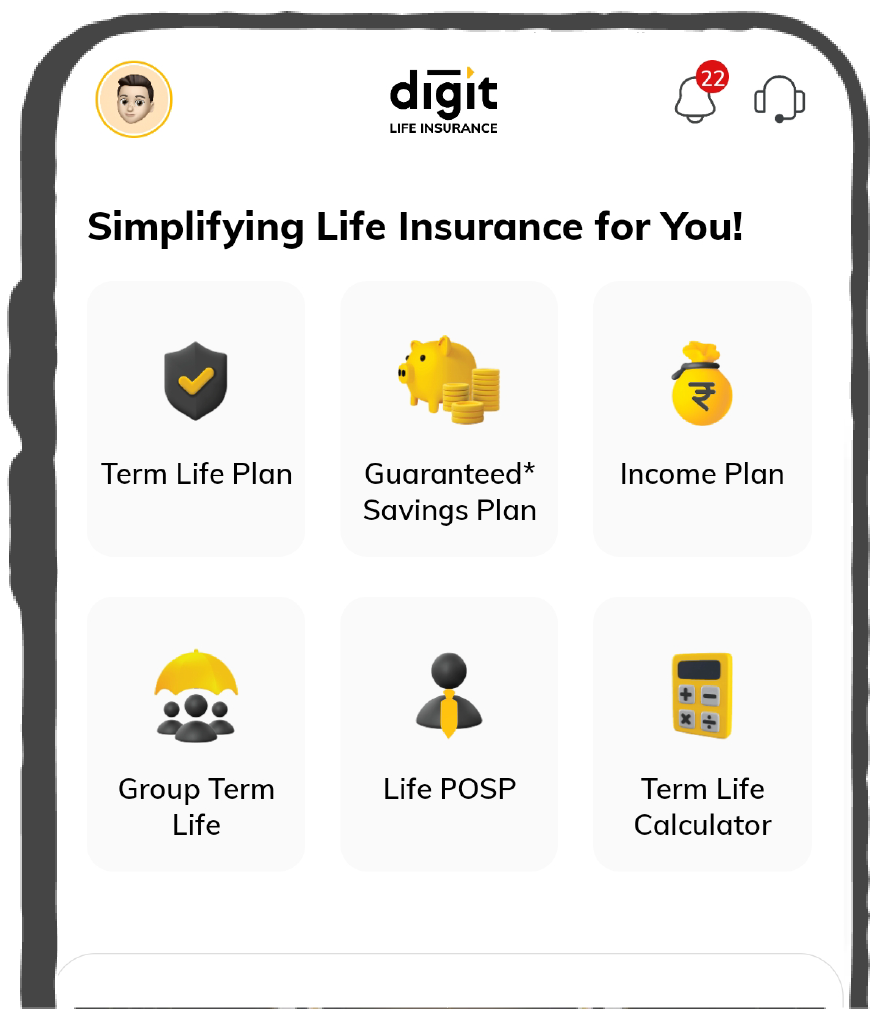

Life

Life Products

Digit Life is here! To help you save & secure your loved ones' future in the most simplified way.

37K+ Reviews

7K+ Reviews

Scan to download

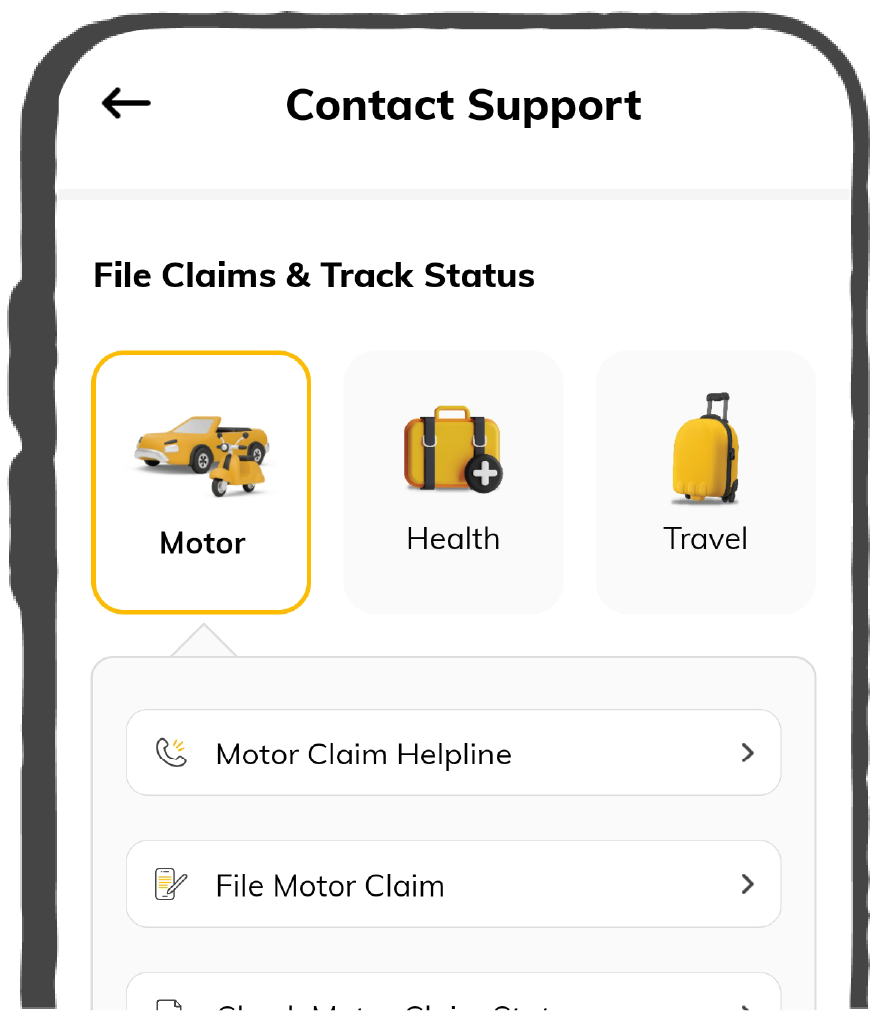

Claims

Claims

We'll be there! Whenever and however you'll need us.

37K+ Reviews

7K+ Reviews

Scan to download

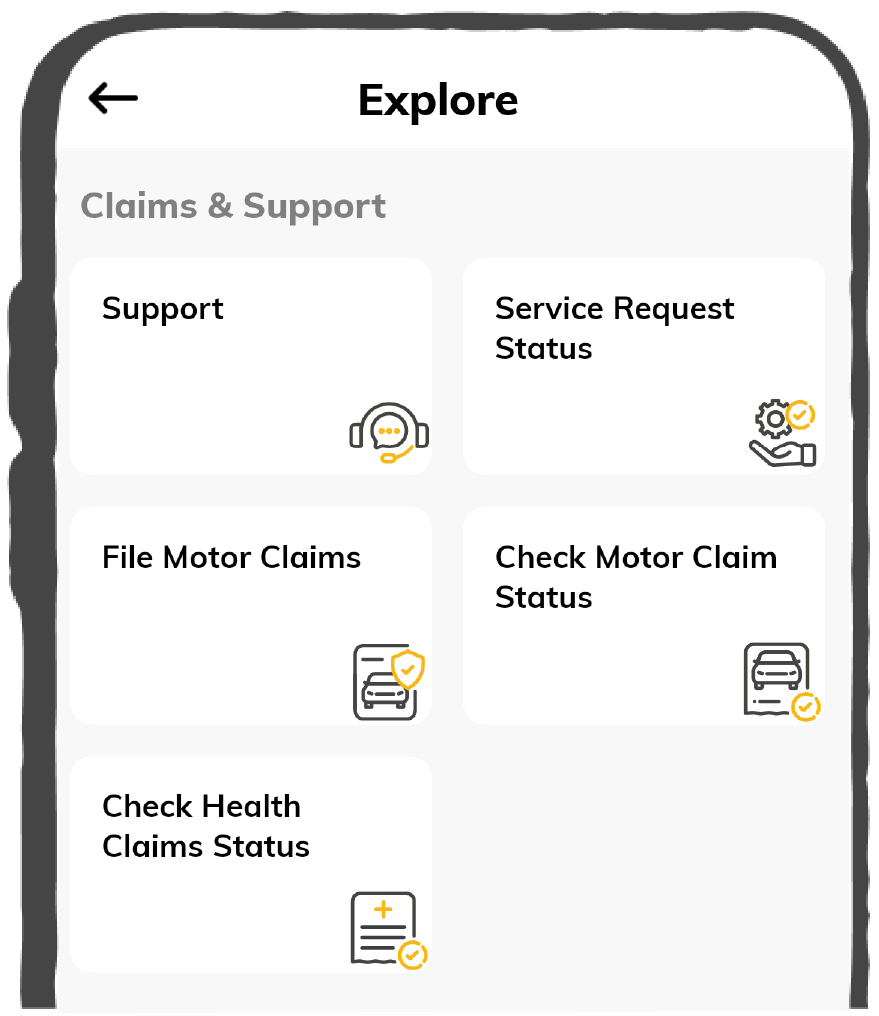

Resources

Resources

All the more reasons to feel the Digit simplicity in your life!

Tools & Calculators

Tools & Calculators

37K+ Reviews

7K+ Reviews

Scan to download

37K+ Reviews

7K+ Reviews

Logout

Logout

Our WhatsApp number cannot be used for calls. This is a chat only number.

9000+ Cashless

Network Garages

96% Claim

Settlement (FY23-24)

24*7 Claims

Support

Click here for new car

I agree to the Terms & Conditions

Add Mobile Number

Sorry!

9000+ Cashless

Network Garages

96% Claim

Settlement (FY23-24)

24*7 Claims

Support

Terms and conditions

The working system of every possible machine involves elaborate and complex mechanisms that cumulatively enhance its productivity. Similarly, an oil pump is one of the requisites of every machinery, since it plays an essential task of oil circulation.

They allow lubrication of the machines, thus allowing them to function seamlessly without undergoing corrosion.

Here are some essential functions of an oil pump:

It circulates oil and ensures that an engine functions smoothly with sufficient lubrication.

It ensures that engines do not undergo wear and tear due to constant subjection to friction.

It circulates the oil in a specific direction through engine galleries.

It stores the hot oil in the reservoir

Mentioned below, are the three most popular types of oil pumps available in the market.

Rotor pumps are usually positioned inside the crankcase so that they can conveniently draw the oil and circulate it to the parts of an engine. They comprise special distinctive rotating inner and outer gears. However, to ensure maximum efficiency, the inner gear comprises one less lobe that is positioned slightly off the centre.

However, this type of oil pump requires meticulous calculation and accurate measurements to ensure seamless functionality.

A twin-gear pump lies within an oil pan at the bottom of an engine. This type of oil comprises two meshing gears that operate together to effectively pump oil to the engine parts. Interestingly, a shaft connected to a camshaft, connecting gear, or crankshaft, moves the first gear. Similarly, the first gear effectively moves the second gear.

Front cover oil pumps, also known as internal or external pumps, are almost similar to rotor pumps. They consist of an outer rotor and an inner gear that is directly attached to a crankshaft. Consequently, it eliminates the need for a separate pump driveshaft.

With this unique structure, a pump rotates at the same speed as that of an engine thereby producing high oil pressure.

Here is a vivid explanation of the working of oil pumps. The pumps are connected to an engine. They start pumping oil when an engine starts running.

Certain engines come with an injector that receives a portion of the oil. This locks the space between the piston ring and cylinder walls, thus preventing air from escaping. Consequently, this enhances the efficiency of an engine.

Failure of an oil pump often signifies that it is incapable of adequately circulating the oil to the engine parts. This leads to a severe degradation of the engine performance. Here are a few symptoms that indicate your engine's oil pumps might not be functioning properly.

A warning sign on an oil light indicator signifies the malfunctioning of a pump. An oil pump regulates the pressure of oil and ensures its smooth circulation in your engine parts. However, a glitch in your oil pumps deteriorates the pressure of the oil.

The circulation of sufficient oil by a pump is necessary for a hassle-free functioning of an engine. With insufficient oil flow, an engine undergoes constant friction and wear and tear, which elevates its internal and external temperature. This excess heat may damage your engine and most of its vital components.

A valve train comprises essential engine components like hydraulic lifters, valve guides, push rods, and seals. These integral parts require oil for lubrication that allows them to function effectively. However, inadequate oil provides insufficient lubrication, thus increasing friction between engine parts. As a result, this valve train makes a noise suggesting a malfunctioning of its oil pump.

A whirring sound from the engine even while it is not running, suggests severe malfunctioning of an oil pump. While this is a rare event, noise is an ultimate warning signal prompting you to take immediate action. In such cases, you must replace the pumps with new ones.

A noisy hydraulic lifter is yet another warning symbol hinting towards an oil pump failure. These hydraulic lifters are a primary driving force behind the functioning of a valve train. However, they do not receive adequate lubrication when a pump fails to deliver sufficient oil. Consequently, this causes malfunctioning hydraulic lifters to produce noise.

To conclude, an oil pump plays a vital role in the overall functioning of an engine. Moreover, with rapid development in technology, the usage and efficiency of oil pumps will continue to upgrade and reach newer heights. However, despite the involvement of new and cutting-edge technology, one must be mindful of the efficiency of pumps, and take utmost care as much as possible.

Yes, oil in a pump may pick up and gather debris and other particles. However, this usually happens when you do not change the oil for long.

Yes, oil in a pump may pick up and gather debris and other particles. However, this usually happens when you do not change the oil for long.

Yes, a high-viscosity oil will face more resistance during circulation. So, it may result in insufficient lubrication of the components of engines.

Yes, a high-viscosity oil will face more resistance during circulation. So, it may result in insufficient lubrication of the components of engines.

The mechanic usually takes somewhere between 4-8 hours to replace oil pumps. Remember, you must keep in mind that with proper maintenance, the pumps can last for many years which will further reduce the requirement of replacement.

The mechanic usually takes somewhere between 4-8 hours to replace oil pumps. Remember, you must keep in mind that with proper maintenance, the pumps can last for many years which will further reduce the requirement of replacement.

Please try one more time!

Other Important Articles About Different Car Parts

Other Important Articles about Car Insurance

Have queries related to Digit motor insurance policy? You can refer to our Policy Wordings for detailed information or reach out to our support team via WhatsApp self-support, email or phone using the information below:

Connect with our self-serve chat bot support - 7026061234

Write to us at hello@godigit.com

Contact

Call us on 1800-258-5956

Other Motor Insurance Plans and Guides

Currently there are no news to show.

Read More

Renew & Download Policy Document, Check Challan, Credit Score, PUC & more

Anytime, Anywhere. Only on Digit App!

4.7

Rated App56K+ Reviews

4.7

Rated App

56K+ Reviews

4.3

Rated App11K+ Reviews

4.3

Rated App

11K+ Reviews

Scan to Download

Author: Team Digit

Last updated: 07-04-2025

CIN: L66010PN2016PLC167410, IRDAI Reg. No. 158.

Go Digit General Insurance Limited | Corporate Office Address: Atlantis, 95, 4th B Cross Road, Koramangala Industrial Layout, 5th Block, Bengaluru 560095 | Registered Office Address: 1 to 6 floors, Ananta One (AR One), Pride Hotel Lane, Narveer Tanaji Wadi, Shivaji Nagar, Pune-411005, Maharashtra | Trade logo of Go Digit General Insurance Ltd. displayed above belongs to Go Digit lnfoworks Services Private Limited and is provided and used by Go Digit General Insurance Ltd. under license.

Explore exclusive features, file claims & access policy on Digit App!

You can also scan this QR code to download the App.