9000+ Cashless

Network Garages

96% Claim

Settlement (FY24-25)

24*7 Claims

Support

Click here for new car

I agree to the Terms & Conditions

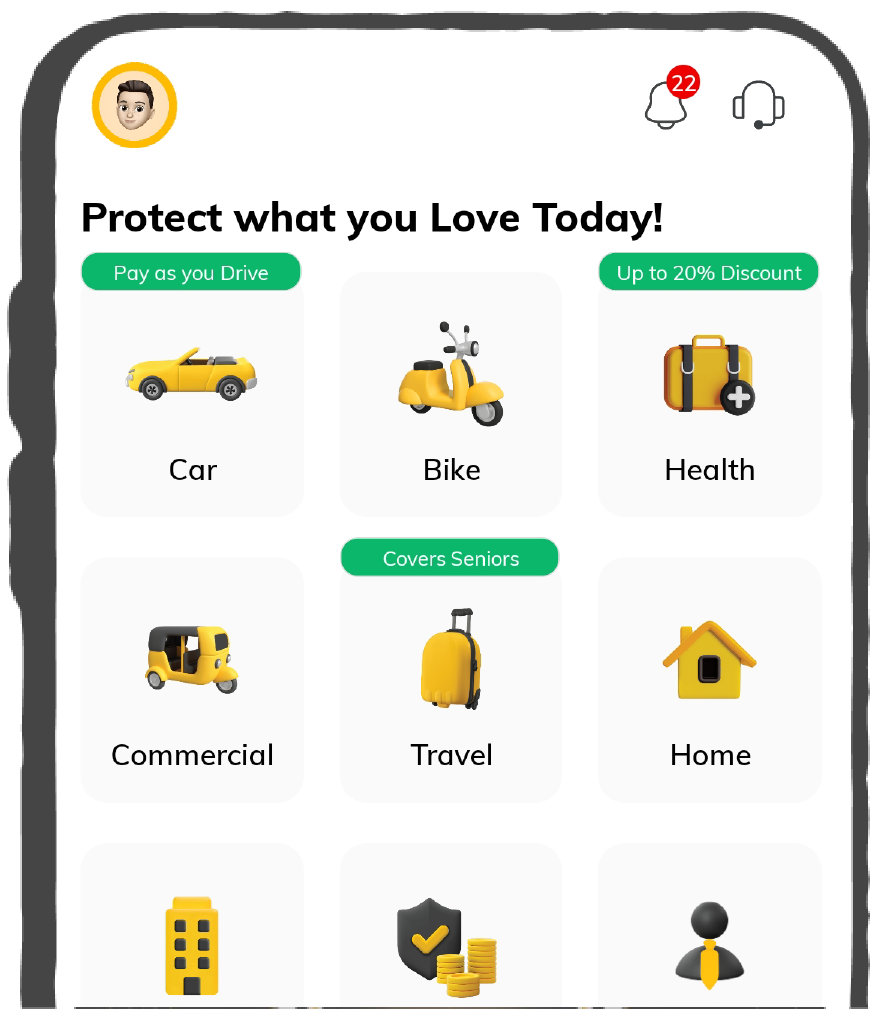

General

General Products

Simple & Transparent! Policies that match all your insurance needs.

37K+ Reviews

7K+ Reviews

Scan to download

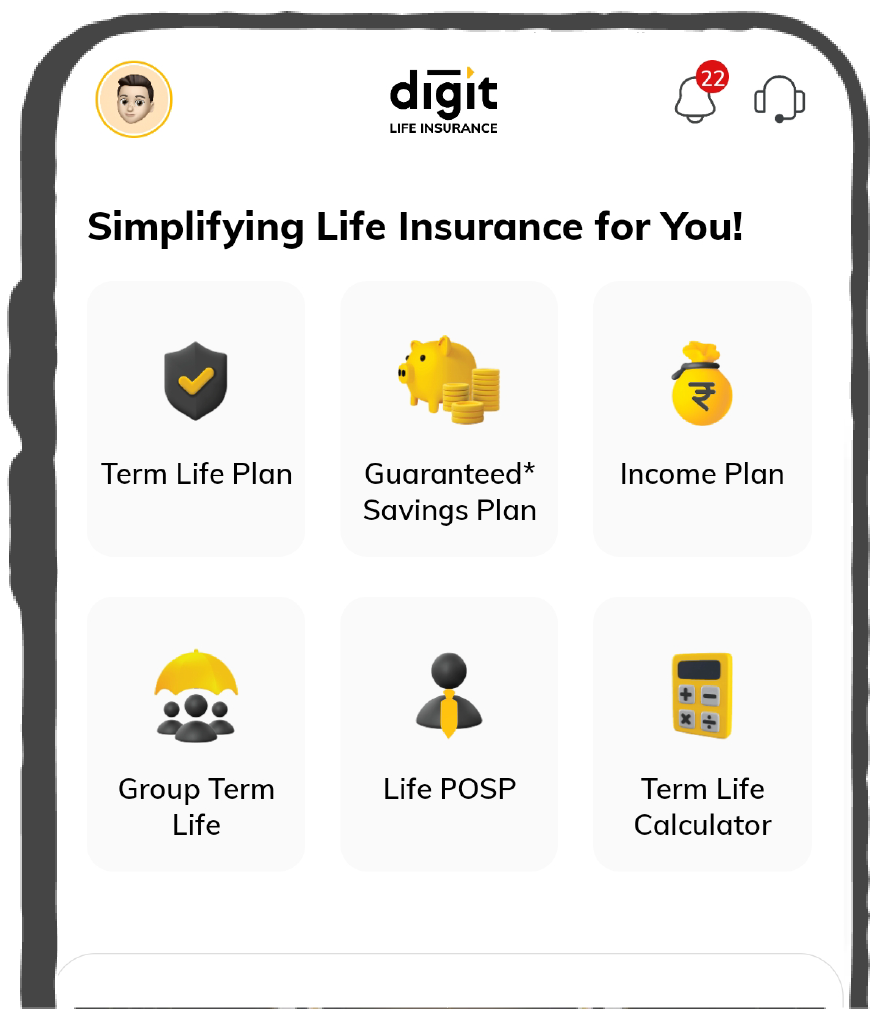

Life

Life Products

Digit Life is here! To help you save & secure your loved ones' future in the most simplified way.

37K+ Reviews

7K+ Reviews

Scan to download

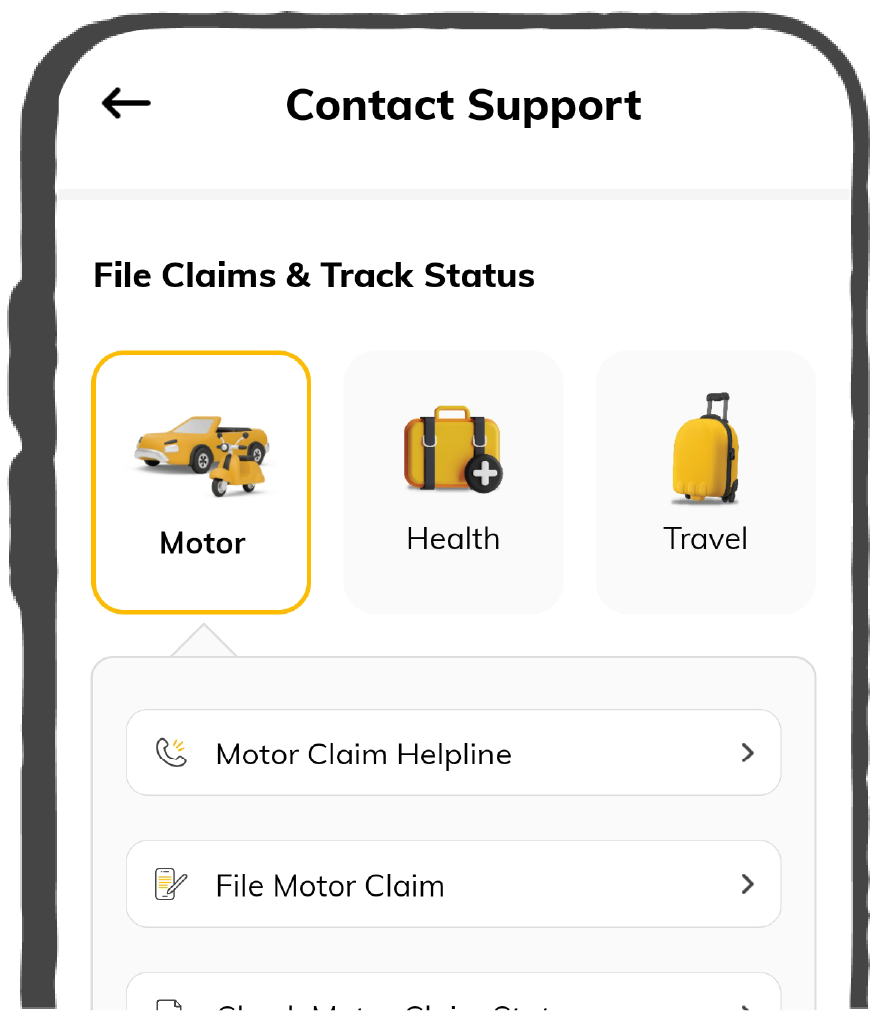

Claims

Claims

We'll be there! Whenever and however you'll need us.

37K+ Reviews

7K+ Reviews

Scan to download

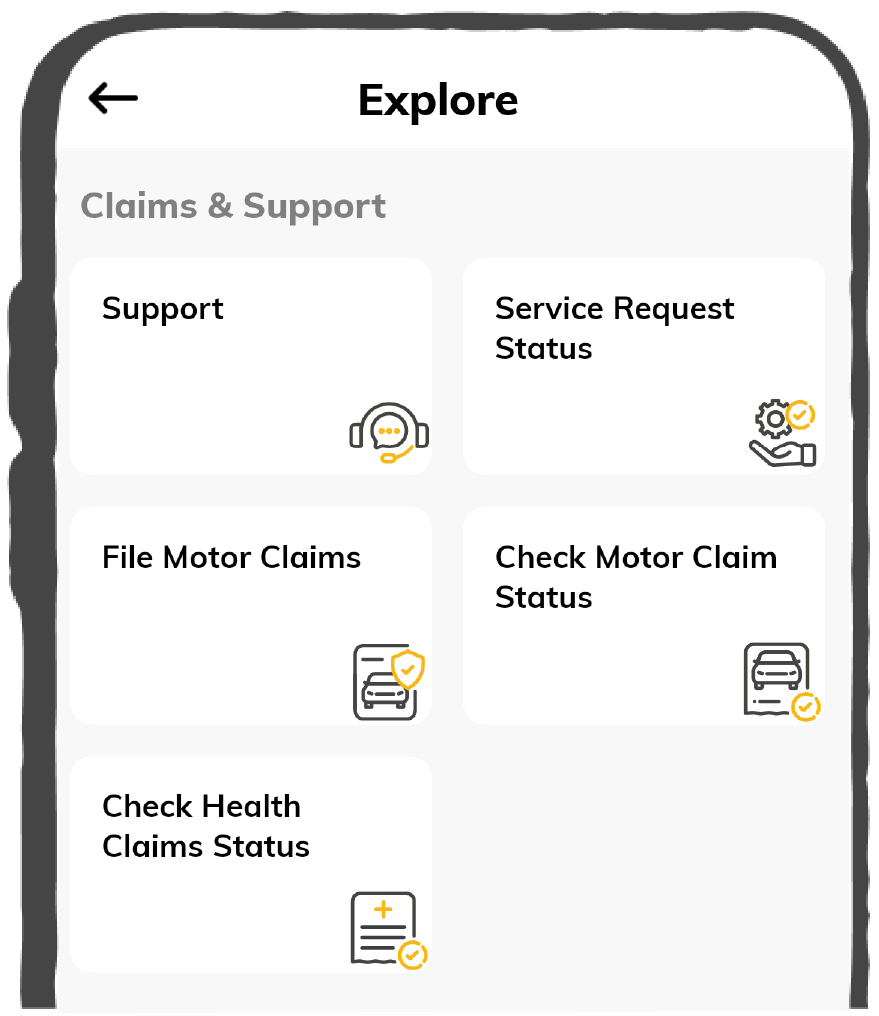

Resources

Resources

All the more reasons to feel the Digit simplicity in your life!

Tools & Calculators

Tools & Calculators

37K+ Reviews

7K+ Reviews

Scan to download

37K+ Reviews

7K+ Reviews

Our WhatsApp number cannot be used for calls. This is a chat only number.

9000+ Cashless

Network Garages

96% Claim

Settlement (FY24-25)

24*7 Claims

Support

Click here for new car

I agree to the Terms & Conditions

Add Mobile Number

Sorry!

9000+ Cashless

Network Garages

96% Claim

Settlement (FY24-25)

24*7 Claims

Support

Terms and conditions

When it comes to cars, every component plays a crucial role in ensuring smooth functionality. One such essential component is the belt drive system, the backbone of various mechanical operations within a car, facilitating power transfer from one part to another.

Understanding belt drive function, types, and intricacies is essential for any car enthusiast or technician.

Belt drives are mechanisms used to transmit power between rotating shafts. It transfers power from the engine to various components like the alternator, water pump, and air conditioning compressor.

They operate based on friction and are integral to the functioning of many automotive systems.

Belts come in various types, each designed to suit specific applications. The three types of belts used in the belt drive mechanism are:

Flat belts offer several advantages and disadvantages in automotive applications:

The advantages of flat belts are as follows:

The disadvantages of flat belts are as follows:

V belts feature a trapezoidal section crafted as continuous loops from rubber strengthened with fibrous material. They operate within V-grooves carved into the pulleys.

The gripping effect of the belts within the V-grooves empowers them to convey greater torques, due to which, this belt is widely used in cars. The power transmitted by a V-belt drive can be augmented by utilising multiple belts arranged side by side.

Belts used in automotive applications are typically made from various materials, including:

Various configurations of belt drives exist, each offering distinct functions, four common types of belt drives are:

Slip and creep are common occurrences in belt drives, affecting their efficiency and performance:

Slip in a belt drive occurs when the belt fails to maintain traction with the pulley surfaces, resulting in a loss of power transmission efficiency. Factors such as insufficient tension, excessive load, or surface contaminants can contribute to slip in belt drives.

Monitoring belt tension, load conditions, and pulley alignment is essential for preventing slip and ensuring reliable operation of the drive system in automotive applications.

Creep refers to the gradual deformation of the belt over time, particularly in applications involving high torque or constant tension. This phenomenon can lead to misalignment of pulleys and uneven wear on the belt, ultimately compromising the integrity of the drive system.

Implementing proper tensioning mechanisms and using high-quality, durable belts can help mitigate belt creep and prolong the service life of the drive components.

When selecting a belt drive for a specific automotive application, several factors need to be considered, such as:

Belt drives play a crucial role in automotive systems, offering efficient power transmission with various types and configurations suited for different applications. Understanding slip, creep, and the factors influencing belt drive selection is essential for optimising performance and reliability in automotive engineering.

Yes, belt drives are suitable for high-speed car applications because they can handle various speeds and power needs.

Yes, belt drives are suitable for high-speed car applications because they can handle various speeds and power needs.

It's typically advantageous to replace the drive belts in your car roughly every 80,000 to 160,000 kilometres.

It's typically advantageous to replace the drive belts in your car roughly every 80,000 to 160,000 kilometres.

Yes, you can replace a drive belt independently, which typically requires approximately 15 minutes.

Yes, you can replace a drive belt independently, which typically requires approximately 15 minutes.

Please try one more time!

Other Important Articles About Different Car Parts

Other Important Articles about Car Insurance

Have queries related to Digit motor insurance policy? You can refer to our Policy Wordings for detailed information or reach out to our support team via WhatsApp self-support, email or phone using the information below:

Connect with our self-serve chat bot support - 7026061234

Write to us at hello@godigit.com

Contact

Call us on 1800-258-5956

Other Motor Insurance Plans and Guides

Currently there are no news to show.

Read More

Renew & Download Policy Document, Check Challan, Credit Score, PUC & more

Anytime, Anywhere. Only on Digit App!

4.8

Rated App60K+ Reviews

4.8

Rated App

60K+ Reviews

4.3

Rated App12K+ Reviews

4.3

Rated App

12K+ Reviews

Scan to Download

Author: Team Digit

Last updated: 02-07-2025

CIN: L66010PN2016PLC167410, IRDAI Reg. No. 158.

Go Digit General Insurance Limited | Corporate Office Address: Atlantis, 95, 4th B Cross Road, Koramangala Industrial Layout, 5th Block, Bengaluru 560095 | Registered Office Address: 1 to 6 floors, Ananta One (AR One), Pride Hotel Lane, Narveer Tanaji Wadi, Shivaji Nagar, Pune-411005, Maharashtra | Trade logo of Go Digit General Insurance Ltd. displayed above belongs to Go Digit lnfoworks Services Private Limited and is provided and used by Go Digit General Insurance Ltd. under license.

Explore exclusive features, file claims & access policy on Digit App!

You can also scan this QR code to download the App.