9000+ Cashless

Network Garages

96% Claim

Settlement (FY23-24)

24*7 Claims

Support

Click here for new car

I agree to the Terms & Conditions

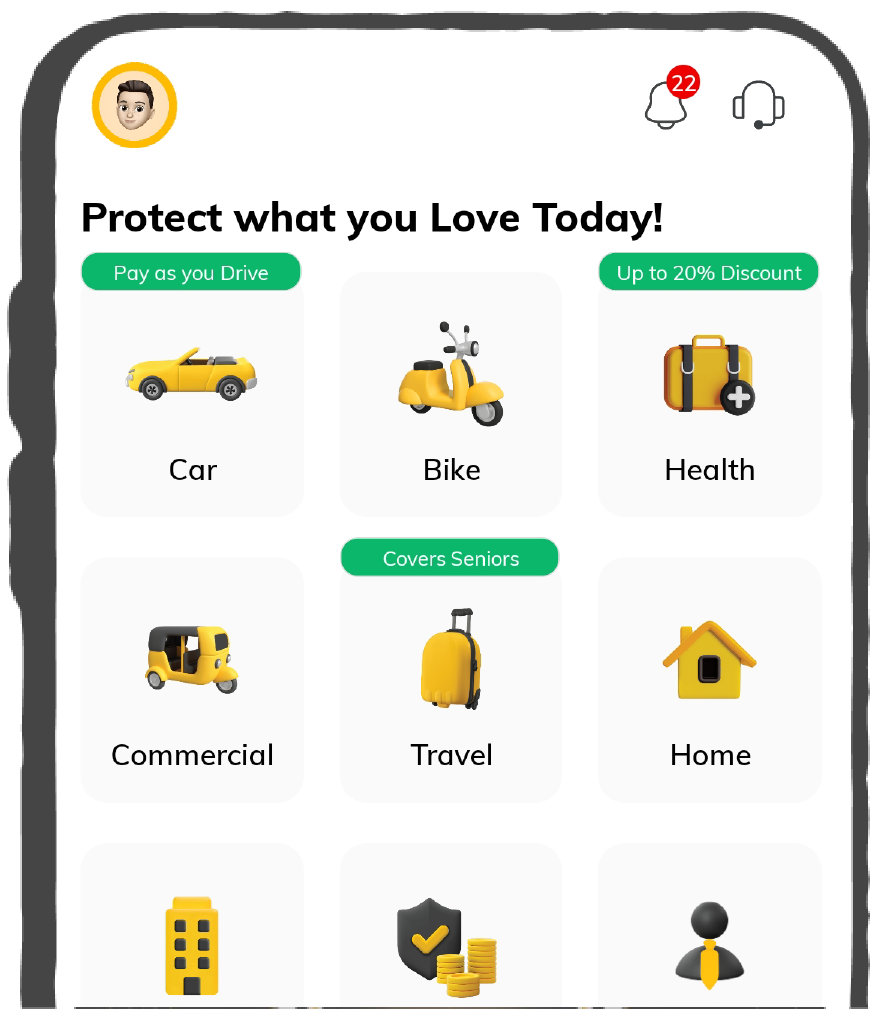

General

General Products

Simple & Transparent! Policies that match all your insurance needs.

4.7

Rated App56K+ Reviews

4.3

Rated App11K+ Reviews

Scan to download

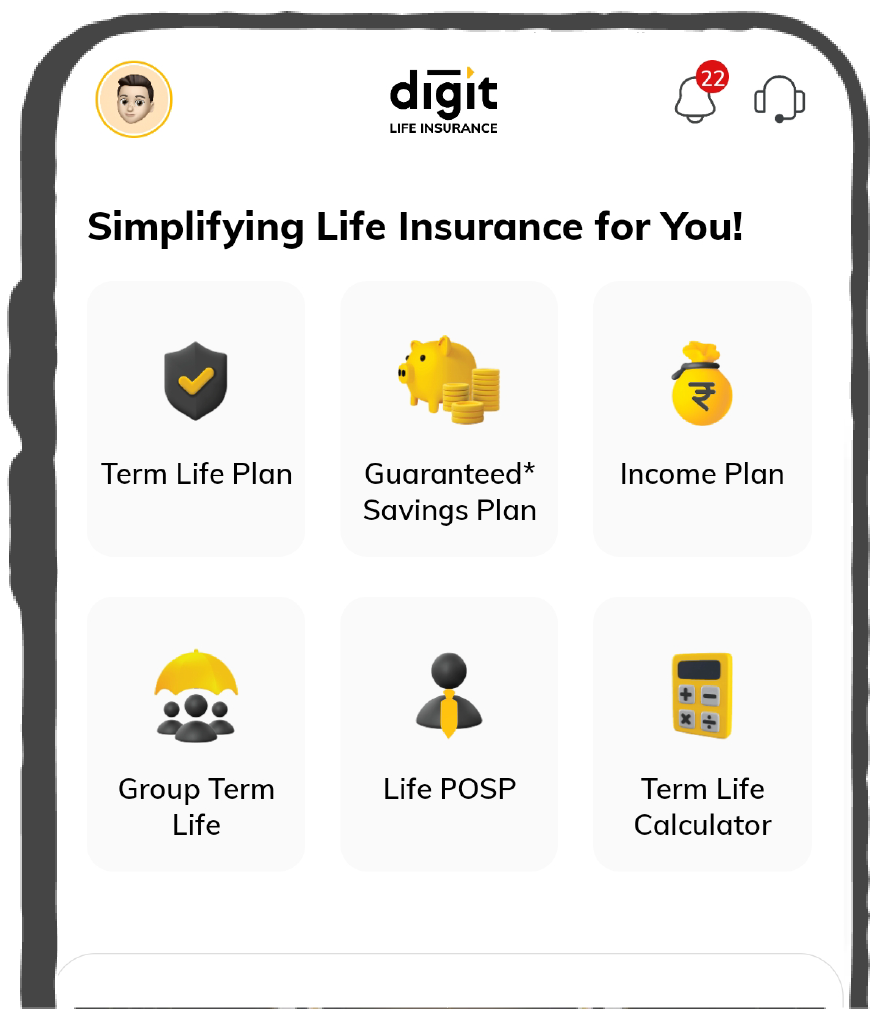

Life

Life Products

Digit Life is here! To help you save & secure your loved ones' future in the most simplified way.

4.7

Rated App56K+ Reviews

4.3

Rated App11K+ Reviews

Scan to download

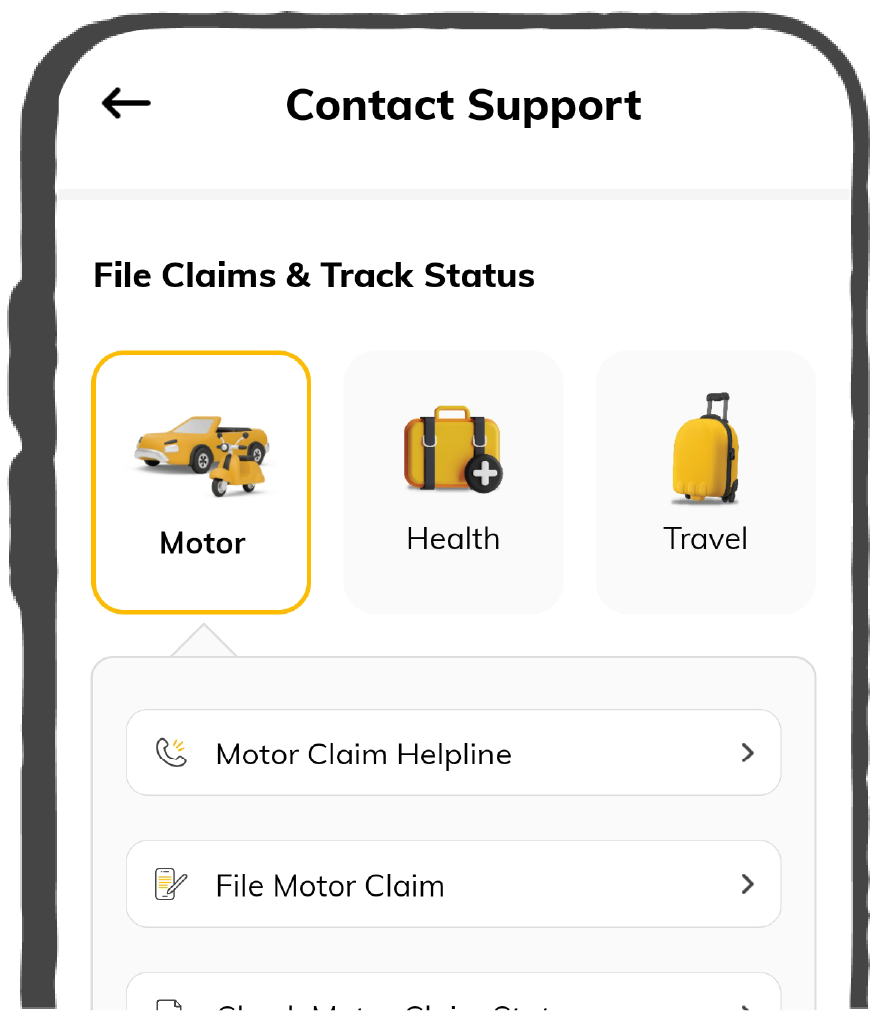

Claims

Claims

We'll be there! Whenever and however you'll need us.

4.7

Rated App56K+ Reviews

4.3

Rated App11K+ Reviews

Scan to download

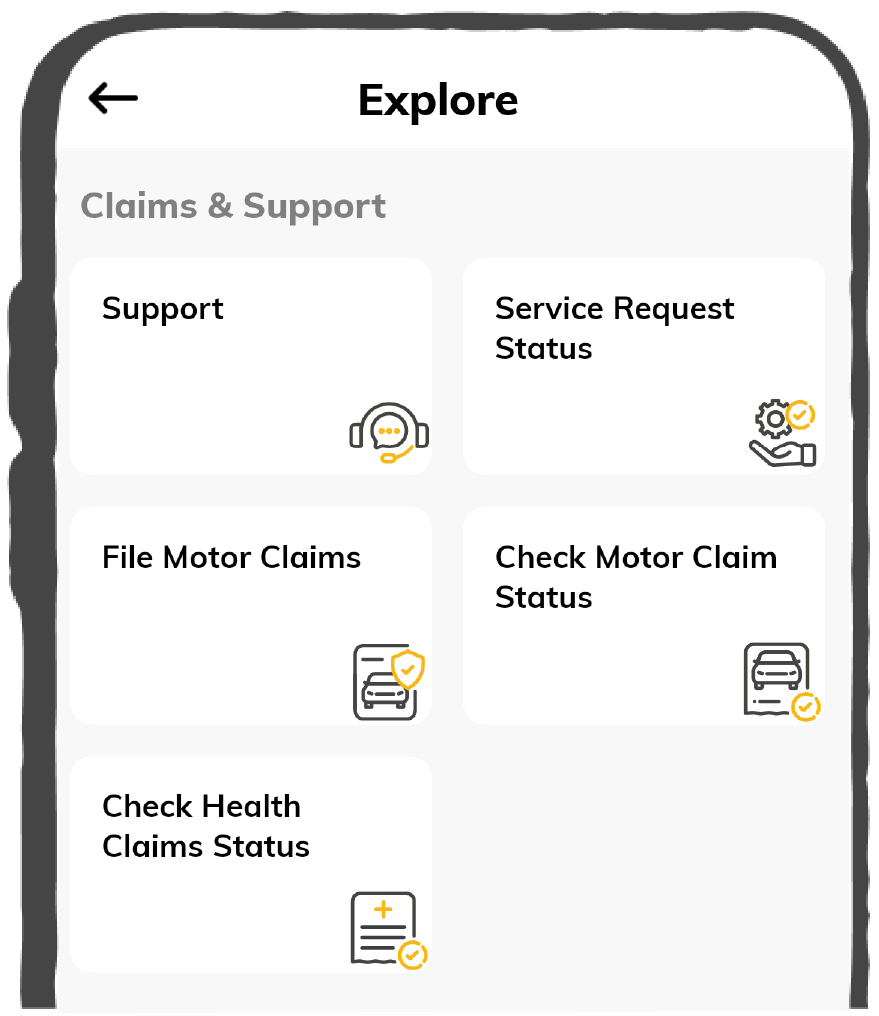

Resources

Resources

All the more reasons to feel the Digit simplicity in your life!

Tools & Calculators

Tools & Calculators

4.7

Rated App56K+ Reviews

4.3

Rated App11K+ Reviews

Scan to download

4.7

Rated App56K+ Reviews

4.3

Rated App11K+ Reviews

Logout

Logout

Our WhatsApp number cannot be used for calls. This is a chat only number.

9000+ Cashless

Network Garages

96% Claim

Settlement (FY23-24)

24*7 Claims

Support

Click here for new car

I agree to the Terms & Conditions

Add Mobile Number

Sorry!

9000+ Cashless

Network Garages

96% Claim

Settlement (FY23-24)

24*7 Claims

Support

Terms and conditions

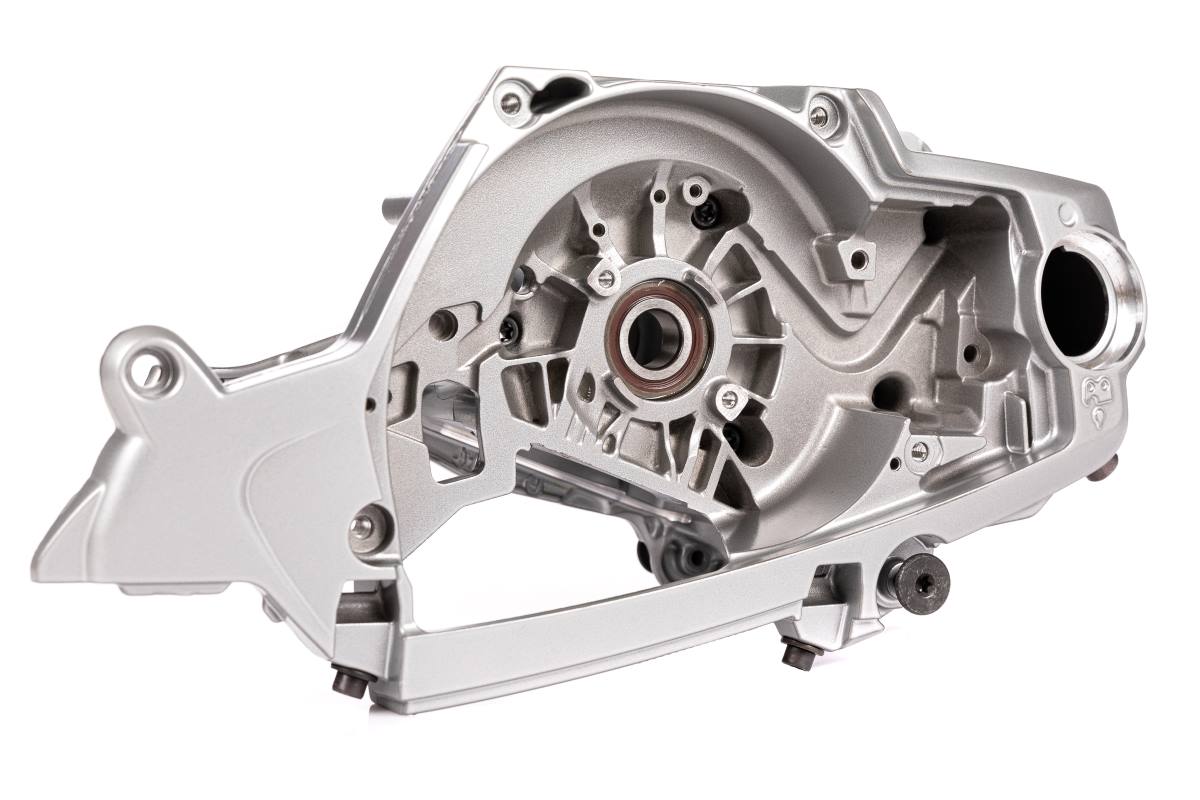

When a vehicle operates, it creates certain harmful gases and oil mist as the air-fuel mixture comes in contact with the combustion gases. These gases may leak further into the piston rings, which can harm your car engine and diminish fuel efficiency. To combat the occurrence, vehicles nowadays come installed with crankcase ventilation.

The following sections detail the positive crankcase ventilation system and how it helps manage engine blow-by.

Crankcase ventilation is the effective process of filtering out these accumulated gases called blow-by from the crankcase. Note that the blow-by gases can easily mix with other contaminants, causing harm to the vehicle and the environment.

The function of a highly efficient crankcase ventilation system is to prevent that from happening.

Depending on your vehicle and its requirements for blow-by, either of the following types of crankcase ventilation system can be installed:

OCVs are installed in vehicles where the blow-by goes into the atmosphere. This system can be low back pressure, low efficiency, or even come with a highly efficient coalescing system to collect huge amounts of oil mist.

One of the primary benefits of the OCV system is that it decreases the chances of oil-build up in the aftercoolers and turbochargers of the engine.

Unlike OCVs, closed crankcase ventilation (CCV) is installed when the blow-by gases are taken back to the engine’s intake in such vehicles. The gases are routed up the compressor wheel and down the air cleaner. Some amount of blow-by may also be sent to the exhaust.

Since this system follows the engine’s path, it helps monitor the total emissions a vehicle produces. This is why, as environmental regulations become stringent, the usage of such systems has increased.

A properly maintained crankcase ventilation system helps manage your vehicle’s engine performance to a great extent. It exhibits the following benefits:

Before venting blow-by gases into the atmosphere or returning them to the engine's intake, crankcase ventilation systems, with their filters, clean them to remove impurities. The main issue with releasing blow-by gases is the creation of oil mist. The filter's job is to collect the oil mist that has been entrained in the blow-by and fuse it before returning it to the engine. Therefore, it plays a role in lowering oil consumption and, in turn, increasing fuel efficiency.

The crankcase ventilation helps remove pollution and contaminants from the crankcase. Efficiency and properly functioning ventilation are crucial in preventing the contaminants from settling on the engine’s aftercoolers and turbochargers, which helps retain the performance of a vehicle’s engine.

Crankcase ventilation systems employ high-efficiency filters to keep smoke, oil mist, and odours from polluting the environment. If the crankcase ventilation system malfunctions, the accumulated gases will release in the atmosphere. Further, untreated blow-by can accumulate on the vehicle’s engine. The oil can become a fire hazard and cause respiratory issues.

Crankcase ventilation helps reduce blow-by emissions, as per regulations defined by national or regional agencies, such as EPA and IMO. Such requirements are defined on the basis of fuel type, stationary or marine installation.

The role of a crankcase ventilation system is huge when it comes to controlling pollutants and contaminants in the crankcase. A properly functioning system ensures your vehicle runs smoothly and performs well on-road.

Yes, since diesel engine vehicles are affected by blow-by. In fact, blow-by is common across all engines, be it petrol or diesel. In diesel engines, blow-by can emerge when the air-fuel in the cylinder bore exceeds the oil pan’s pressure.

Yes, since diesel engine vehicles are affected by blow-by. In fact, blow-by is common across all engines, be it petrol or diesel. In diesel engines, blow-by can emerge when the air-fuel in the cylinder bore exceeds the oil pan’s pressure.

The most prevalent crankcase ventilation system in modern engines is PCS or Positive Crankcase Ventilation.

The most prevalent crankcase ventilation system in modern engines is PCS or Positive Crankcase Ventilation.

All vehicle engines produce some minor levels of blow-by. For example, a 12l engine in good condition can emit 1.5 cubic per minute blow-by gases under normal operating conditions.

All vehicle engines produce some minor levels of blow-by. For example, a 12l engine in good condition can emit 1.5 cubic per minute blow-by gases under normal operating conditions.

Please try one more time!

Other Important Articles About Different Car Parts

Other Important Articles about Car Insurance

Have queries related to Digit motor insurance policy? You can refer to our Policy Wordings for detailed information or reach out to our support team via WhatsApp self-support, email or phone using the information below:

Connect with our self-serve chat bot support - 7026061234

Write to us at hello@godigit.com

Contact

Call us on 1800-258-5956

Other Motor Insurance Plans and Guides

Currently there are no news to show.

04-03-2025

$100 Billion in Auto Part Exports? New Study Shows It's Possible

India's auto component industry aims to reach USD 100 billion in exports within 7-8 years, driven by recovery and growth strategies. The industry achieved USD 21.2 billion in exports in FY24, up from a USD 2.5 billion deficit in FY19. Focusing on classical components and emerging EV markets, especially in the US and Europe, could add USD 40-60 billion. Additionally, localizing EV components could contribute another USD 15-20 billion. Major players need to expand exports and enhance global supply chain integration.

27-02-2025

Can't Buy Fuel or FASTag? Check 3rd-Party Insurance Now

Indians will soon need to show valid third-party insurance to buy fuel, get a FASTag, or renew driving licences and pollution certificates. This move aims to improve third-party insurance coverage, which is currently low despite legal requirements. The government plans to link various vehicle-related services to insurance compliance and enforce stricter rules. This initiative is expected to increase insurance penetration, enhance data collection, and ensure better financial security for vehicle owners.

20-02-2025

ICRA Expects ₹30K Cr Auto Part Investment Next Year

Major auto component firms in India plan to invest Rs 25,000-30,000 crore next fiscal for capacity expansion and localisation, focusing on electric vehicle (EV) parts. ICRA projects revenue growth to slow to 7-9% this fiscal and 8-10% in FY2026, driven by demand from domestic OEMs, premiumisation of components, and replacement demand. Investments will also address regulatory changes and development of advanced technology and EV components.

27-01-2025

Auto Exports Hit 19% Rise in 2024; Driven by Robust Demand Revival in EMs

Strong demand from emerging markets, like Latin America and Africa, led to a 19% increase in India's automobile exports in 2024, which was driven by two-wheelers, passenger vehicles, and commercial vehicles. The overall shipments rose to 50,98,810 units from 42,85,809 units exported in 2023, as per SIAM data. However, the export of passenger cars fell by 4%.

25-01-2025

Gabriel India Acquires ₹60 Crore Assets from Marelli Motherson!

Gabriel India has acquired assets from Marelli Motherson Auto Suspension Parts Pvt Ltd for ₹60 crore. This acquisition boosts Gabriel India's annual production capacity by 3.2 million shock absorbers and 1 million gas spring units, significantly enhancing its position in the suspension market. Executive Chairperson Anjali Singh highlighted that this deal not only broadens their product range but also strengthens their technological capabilities, promising greater value for shareholders.

22-01-2025

Hyundai Localizes 1,200+ Parts and EV Batteries

Hyundai Motor India has localized over 1,200 parts and EV battery packs, achieving up to 92% localization in manufacturing, which helped save $672 million in forex and created over 1,400 jobs. The Hyundai Creta Electric will be the first model to feature locally assembled battery packs, boosting the company's EV strategy and market presence.

17-01-2025

Diesel Cars See Growth Thanks to SUV Sales Surge

Diesel's share in total passenger vehicle (PV) sales in India rose to 18% in the first half of December 2024, up from 17.8% in 2023, with sales increasing from 738,000 to 774,000 units. SUVs, which prefer diesel, now make up 55% of car sales, compared to 48.4% in 2023. Improved diesel technology and better road infrastructure have also boosted demand, positioning diesel as a specialized solution rather than declining.

11-01-2025

Private Insurers Raise Motor Commission Payouts by 239%

In FY2024, private sector general insurers in India saw a 239% rise in commission expenses in motor insurance, spending ₹16,578 crore compared to ₹4,890 crore in FY2023. Public sector insurers reported a 31.59% rise, spending ₹3,099 crore. The high commissions led to expensive premiums for policyholders. Public sector insurers had a higher incurred claims ratio at 99.57%, while private players were at 73.30%. The IRDAI expressed concerns over high commissions and is promoting platforms like Bima Sugam to increase transparency and lower rates.

10-01-2025

New Battery Parts Sops: What's in Store for Manufacturers?

The government is considering incentives for battery component manufacturing to support the expanding electric vehicle industry. The Ministry of Heavy Industries is identifying locally-produced components that need financial support. The scheme, similar to existing production-linked incentives, aims to reduce import dependence and strengthen the local ecosystem. The National Programme on Advanced Chemistry Cell (ACC) Battery Storage, launched in 2021, targets 50 GWh of ACC and 5 GWh of Niche ACC manufacturing capacity with a budget of INR 18,100 crore.

07-01-2025

Indian Auto Parts Firms Poised for US Growth

Indian automotive parts manufacturers aim to increase their export share to the US, driven by expectations of significant tariff increases on Chinese goods under President-elect Donald Trump. They are engaging with US suppliers and vehicle makers, focusing on boosting supplies from factories in Mexico and considering acquisitions in Europe. The US is India's largest export market, with $3.67 billion worth of automotive components exported in H1FY25. The China+1 strategy benefits Indian manufacturing, with companies leveraging this opportunity to expand their footprint.

Read More

Renew & Download Policy Document, Check Challan, Credit Score, PUC & more

Anytime, Anywhere. Only on Digit App!

4.7

Rated App56K+ Reviews

4.7

Rated App

56K+ Reviews

4.3

Rated App11K+ Reviews

4.3

Rated App

11K+ Reviews

Scan to Download

Author: Team Digit

Last updated: 07-04-2025

CIN: L66010PN2016PLC167410, IRDAI Reg. No. 158.

Go Digit General Insurance Limited | Corporate Office Address: Atlantis, 95, 4th B Cross Road, Koramangala Industrial Layout, 5th Block, Bengaluru 560095 | Registered Office Address: 1 to 6 floors, Ananta One (AR One), Pride Hotel Lane, Narveer Tanaji Wadi, Shivaji Nagar, Pune-411005, Maharashtra | Trade logo of Go Digit General Insurance Ltd. displayed above belongs to Go Digit lnfoworks Services Private Limited and is provided and used by Go Digit General Insurance Ltd. under license.

Explore exclusive features, file claims & access policy on Digit App!

You can also scan this QR code to download the App.