9000+ Cashless

Network Garages

96% Claim

Settlement (FY23-24)

24*7 Claims

Support

Click here for new car

I agree to the Terms & Conditions

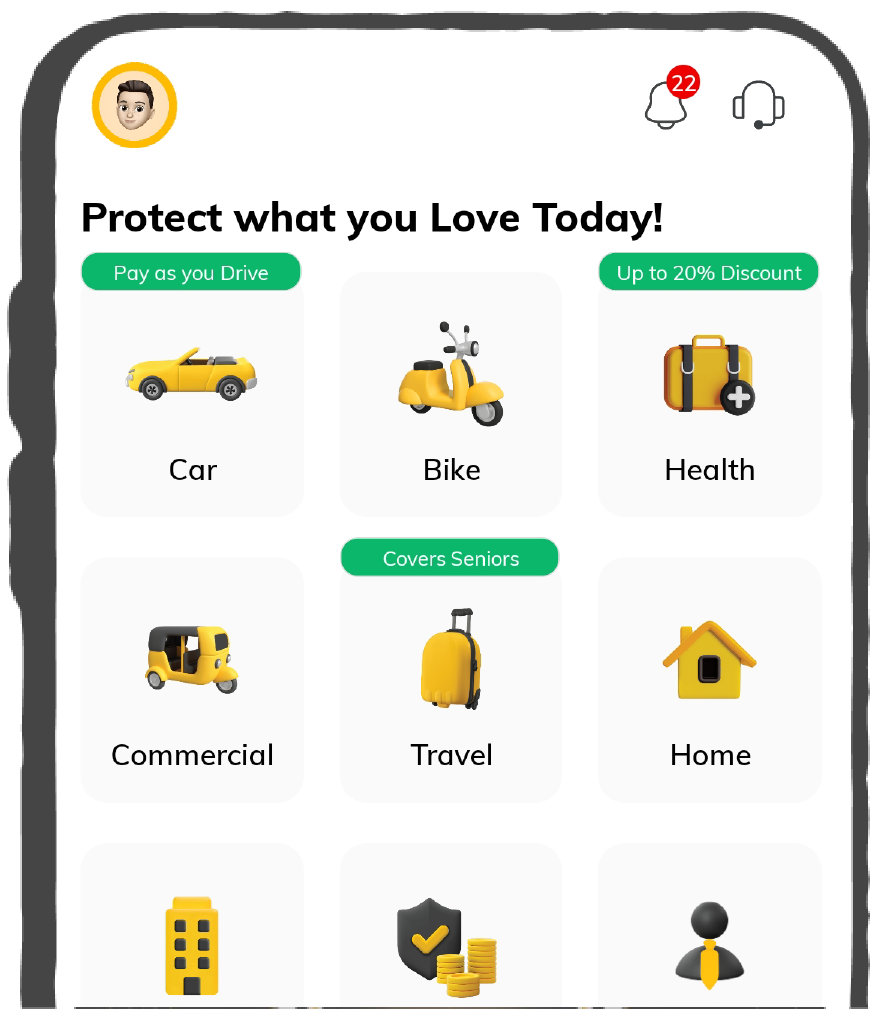

General

General Products

Simple & Transparent! Policies that match all your insurance needs.

37K+ Reviews

7K+ Reviews

Scan to download

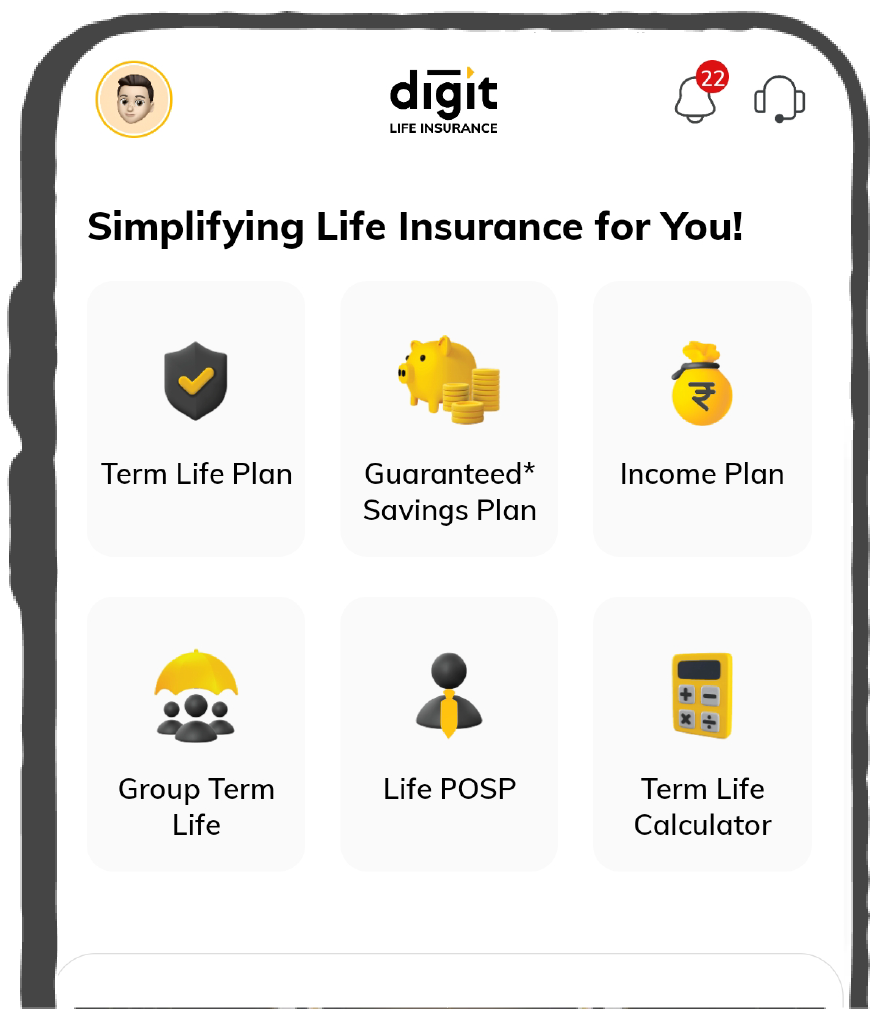

Life

Life Products

Digit Life is here! To help you save & secure your loved ones' future in the most simplified way.

37K+ Reviews

7K+ Reviews

Scan to download

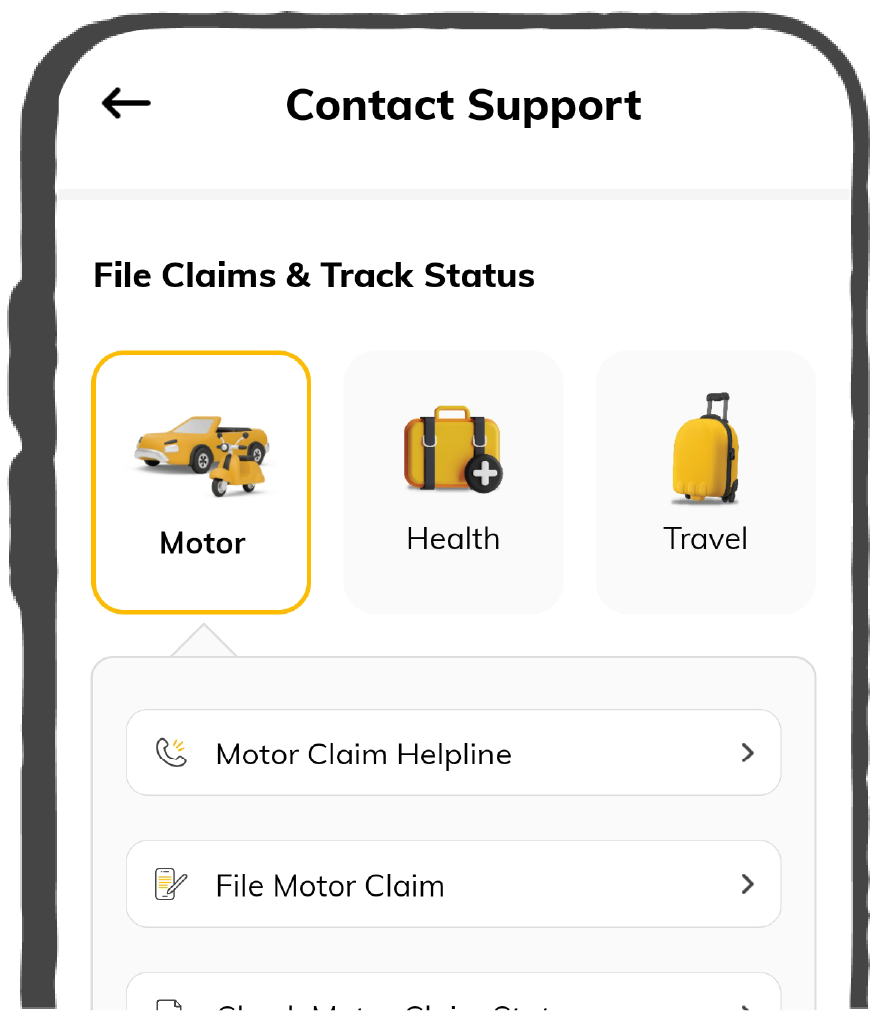

Claims

Claims

We'll be there! Whenever and however you'll need us.

37K+ Reviews

7K+ Reviews

Scan to download

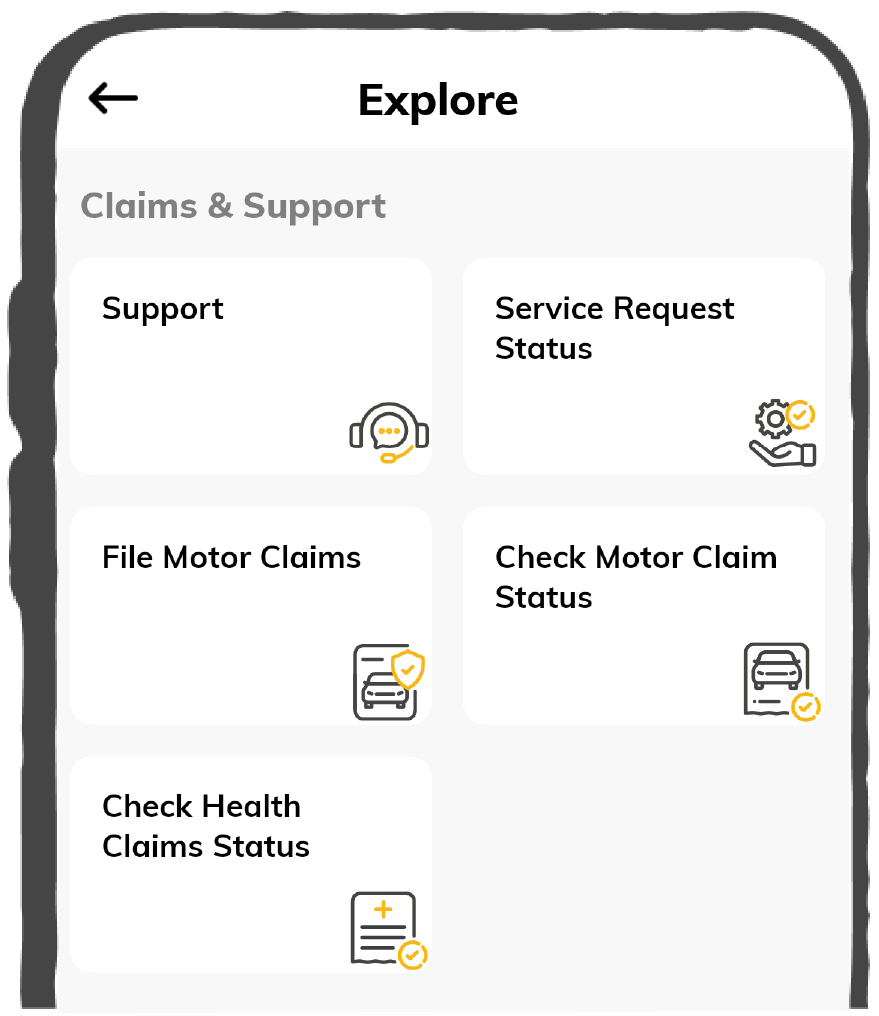

Resources

Resources

All the more reasons to feel the Digit simplicity in your life!

Tools & Calculators

Tools & Calculators

37K+ Reviews

7K+ Reviews

Scan to download

37K+ Reviews

7K+ Reviews

Our WhatsApp number cannot be used for calls. This is a chat only number.

9000+ Cashless

Network Garages

96% Claim

Settlement (FY23-24)

24*7 Claims

Support

Click here for new car

I agree to the Terms & Conditions

Add Mobile Number

Sorry!

9000+ Cashless

Network Garages

96% Claim

Settlement (FY23-24)

24*7 Claims

Support

Terms and conditions

The term "monocoque chassis" holds significant weight in engineering and car design. Derived from the French word "monocoque," meaning "single shell," a monocoque chassis is a structural design principle widely employed in various industries.

Understanding monocoque chassis' construction, advantages, and applications is essential for every car enthusiast.

A monocoque chassis is a structural design principle where a car or object's external skin or body carries most, if not all, of the applied stresses. Unlike traditional chassis designs with a separate frame and body structure, a monocoque chassis integrates both functions into a single unit.

This integration results in a safe, lighter, yet stronger structure, as the entire shell contributes to bearing loads and distributing forces.

The construction of a monocoque chassis involves the following six steps:

Step 1: Material Selection: Choose lightweight yet durable materials like carbon fibre or aluminium, known for their strength-to-weight ratio.

Step 2: Design Phase: Meticulously design the chassis structure using CAD software, considering load distribution and aerodynamics.

Step 3: Manufacturing Process: Utilise moulding, bonding, and autoclaving techniques to form and strengthen the chassis.

Step 4: Integration of Components: Strategically Integrate suspension and engine mounts and safety features for optimal performance.

Step 5: Quality Assurance: To ensure structural integrity, implement stringent quality control measures, including non-destructive testing methods.

Step 6: Final Assembly: Assemble the chassis with other components like the powertrain and suspension system to create a fully functional car.

The monocoque chassis offers numerous advantages, and some of them include:

Following are the five key areas where monocoque chassis are commonly utilised:

The monocoque chassis represents a pinnacle of engineering innovation, offering unparalleled strength, weight savings, and versatility across various industries. From automotive to aerospace, its impact on modern engineering cannot be overstated, as it continues to drive advancements in performance, safety, and design.

The lightweight nature of monocoque chassis designs improves performance metrics such as acceleration, handling, and fuel efficiency, making them highly desirable in performance-oriented applications.

The lightweight nature of monocoque chassis designs improves performance metrics such as acceleration, handling, and fuel efficiency, making them highly desirable in performance-oriented applications.

Repairing damage can be complex and costly due to the integrated design, limiting ease of maintenance. Additionally, modifications are more restricted than traditional chassis designs, reducing customisation options. Moreover, the higher initial cost of cars or equipment with monocoque chassis may deter some consumers.

Repairing damage can be complex and costly due to the integrated design, limiting ease of maintenance. Additionally, modifications are more restricted than traditional chassis designs, reducing customisation options. Moreover, the higher initial cost of cars or equipment with monocoque chassis may deter some consumers.

The weight of a monocoque chassis varies depending on factors such as the materials used, the size of the chassis, and its intended application. However, monocoque chassis are generally lighter than traditional ones and weigh as little as 35 kilograms.

The weight of a monocoque chassis varies depending on factors such as the materials used, the size of the chassis, and its intended application. However, monocoque chassis are generally lighter than traditional ones and weigh as little as 35 kilograms.

Please try one more time!

Other Important Articles About Different Car Parts

Other Important Articles about Car Insurance

Have queries related to Digit motor insurance policy? You can refer to our Policy Wordings for detailed information or reach out to our support team via WhatsApp self-support, email or phone using the information below:

Connect with our self-serve chat bot support - 7026061234

Write to us at hello@godigit.com

Contact

Call us on 1800-258-5956

Other Motor Insurance Plans and Guides

Currently there are no news to show.

Read More

Renew & Download Policy Document, Check Challan, Credit Score, PUC & more

Anytime, Anywhere. Only on Digit App!

4.8

Rated App60K+ Reviews

4.8

Rated App

60K+ Reviews

4.3

Rated App12K+ Reviews

4.3

Rated App

12K+ Reviews

Scan to Download

Author: Team Digit

Last updated: 02-07-2025

CIN: L66010PN2016PLC167410, IRDAI Reg. No. 158.

Go Digit General Insurance Limited | Corporate Office Address: Atlantis, 95, 4th B Cross Road, Koramangala Industrial Layout, 5th Block, Bengaluru 560095 | Registered Office Address: 1 to 6 floors, Ananta One (AR One), Pride Hotel Lane, Narveer Tanaji Wadi, Shivaji Nagar, Pune-411005, Maharashtra | Trade logo of Go Digit General Insurance Ltd. displayed above belongs to Go Digit lnfoworks Services Private Limited and is provided and used by Go Digit General Insurance Ltd. under license.

Explore exclusive features, file claims & access policy on Digit App!

You can also scan this QR code to download the App.