I agree to the Terms & Conditions

General

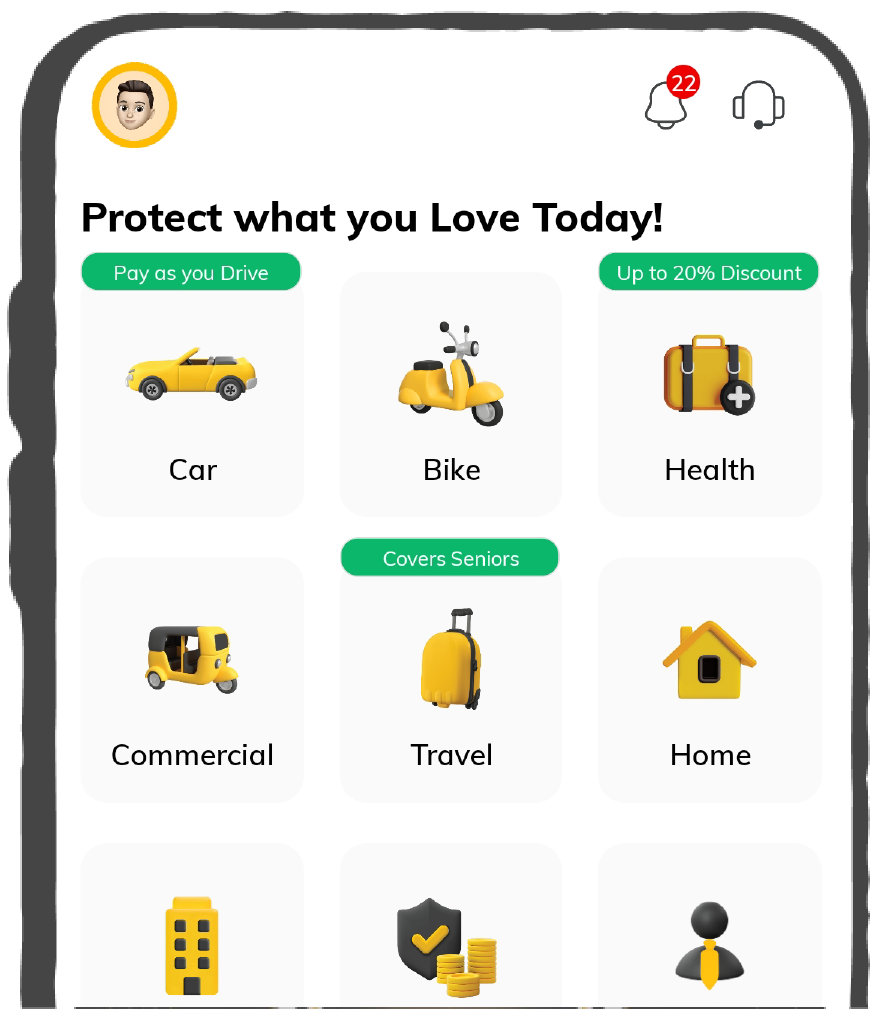

General Products

Simple & Transparent! Policies that match all your insurance needs.

37K+ Reviews

7K+ Reviews

Scan to download

Life

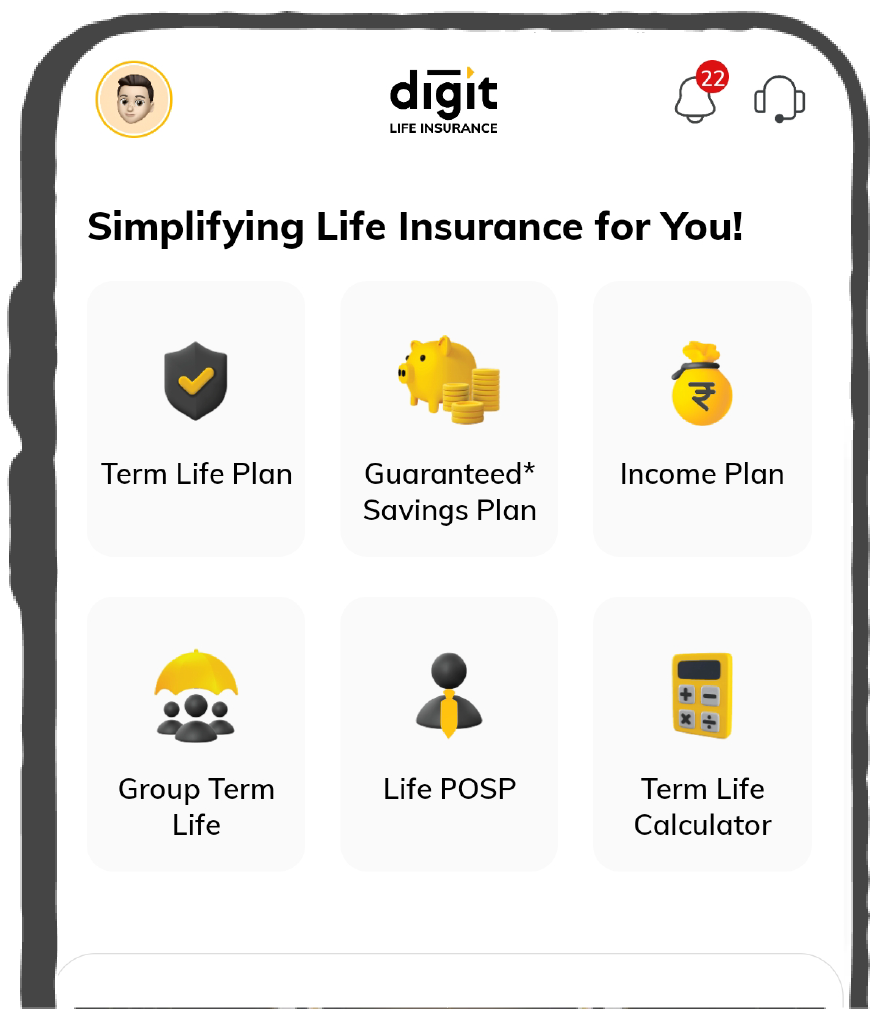

Life Products

Digit Life is here! To help you save & secure your loved ones' future in the most simplified way.

37K+ Reviews

7K+ Reviews

Scan to download

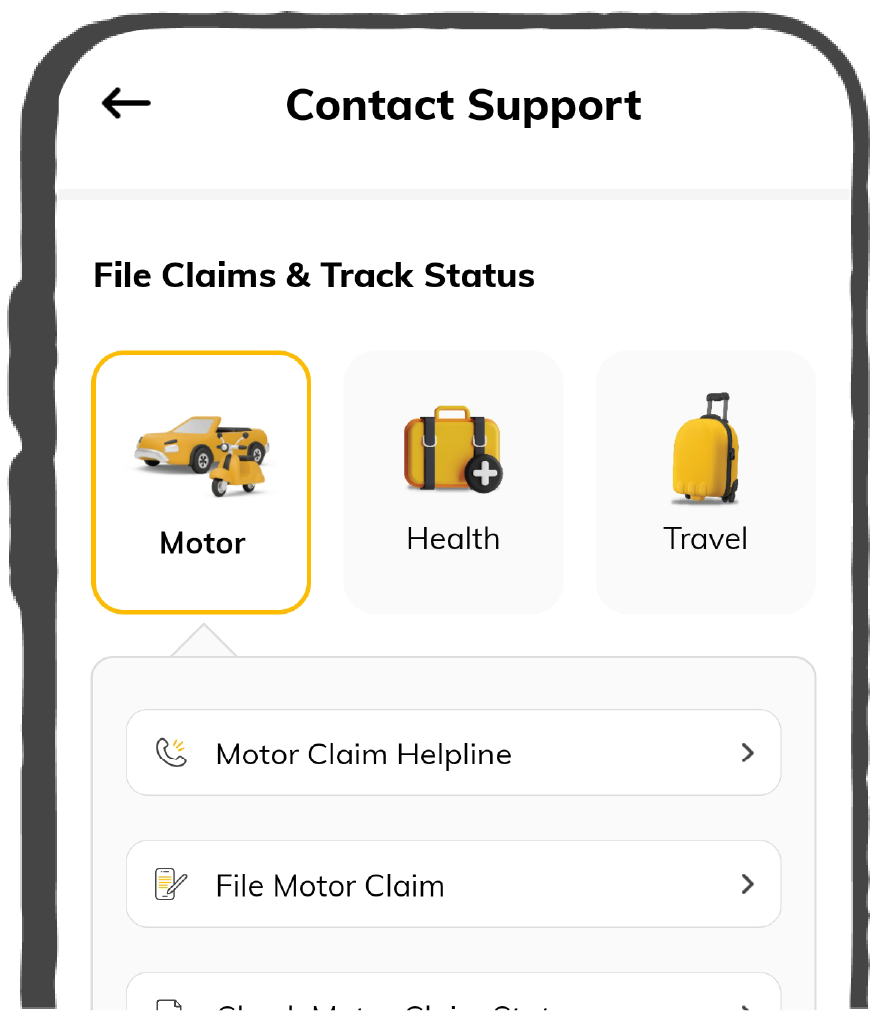

Claims

Claims

We'll be there! Whenever and however you'll need us.

37K+ Reviews

7K+ Reviews

Scan to download

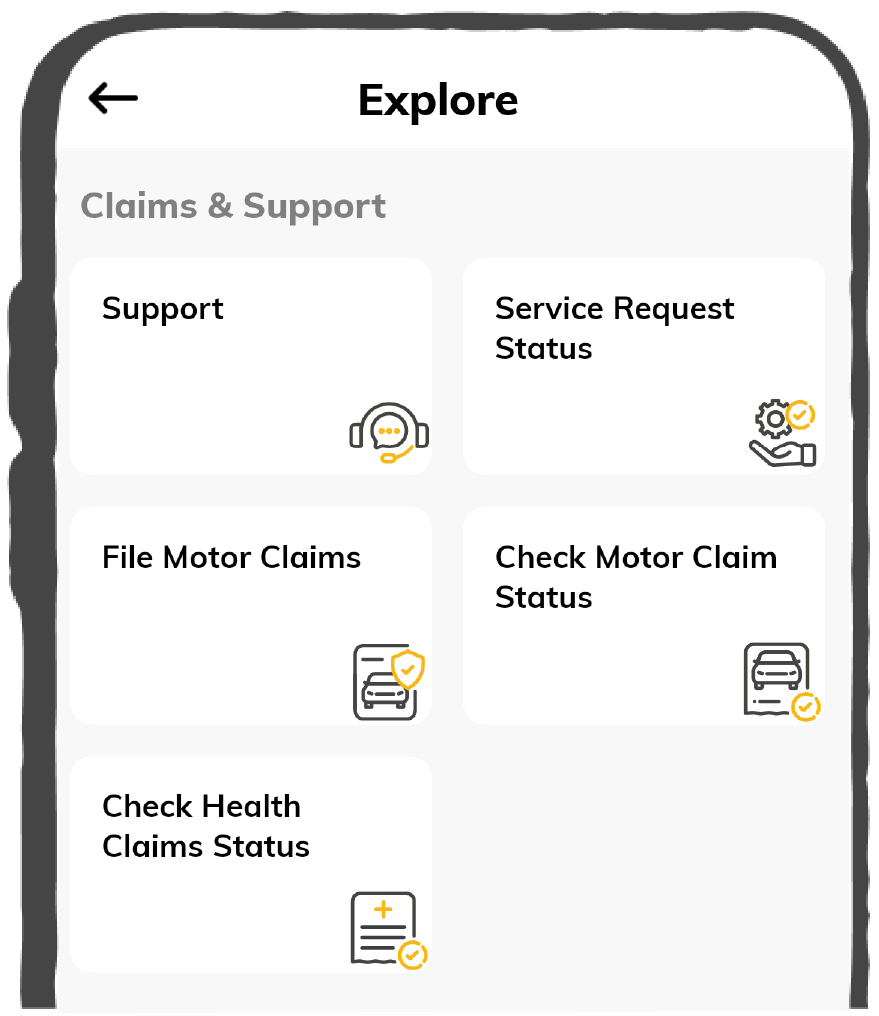

Resources

Resources

All the more reasons to feel the Digit simplicity in your life!

Tools & Calculators

Tools & Calculators

37K+ Reviews

7K+ Reviews

Scan to download

37K+ Reviews

7K+ Reviews

Logout

Logout

Our WhatsApp number cannot be used for calls. This is a chat only number.

2000+ Cashless

Network Garages

96% Claim

Settlement (FY23-24)

24*7 Claims

Support

I agree to the Terms & Conditions

Terms and conditions

Truck suspension is an essential component of any heavy-duty vehicle, playing a critical role in ensuring a smooth and comfortable ride, as well as maintaining the stability and safety of the truck.

In this comprehensive guide, we will delve into the world of truck suspension, exploring its functions, various types, and how it works to provide a seamless driving experience for truckers.

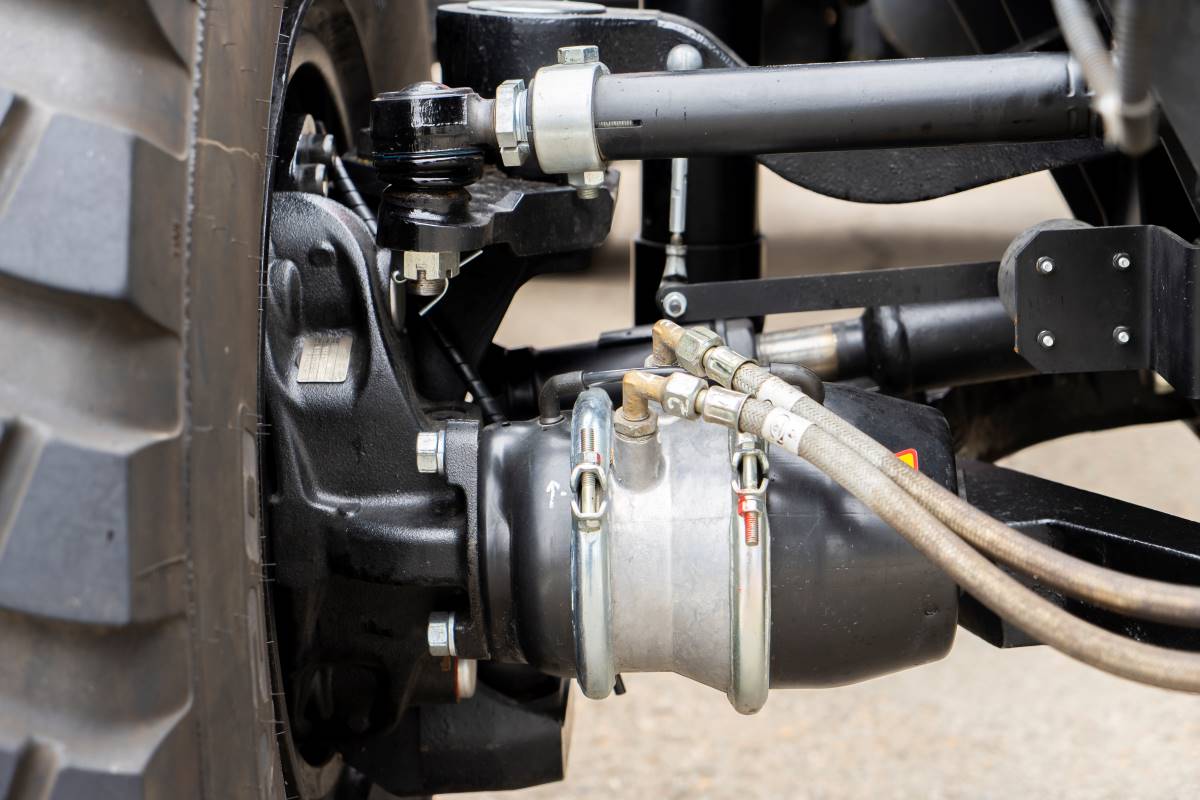

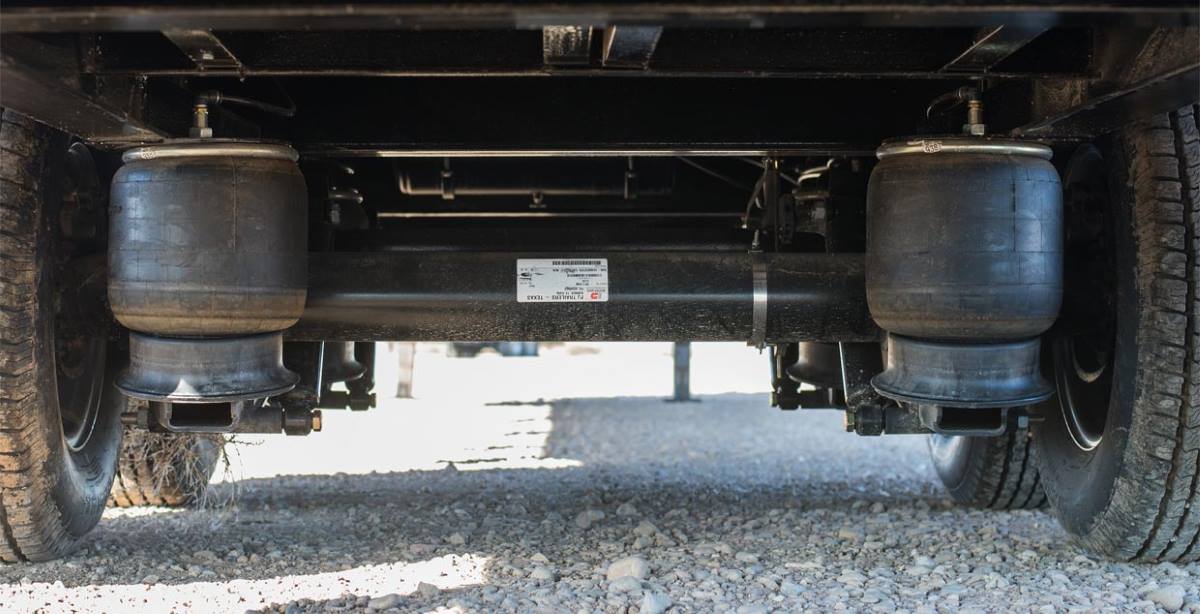

Truck suspension, often referred to as the truck suspension system, is a complex assembly of components designed to support the weight of the truck, absorb road shocks, and ensure the stability of the vehicle.

It acts as the intermediary between the truck's tires and the chassis, providing a comfortable ride for the driver and protecting the cargo from excessive jolts and vibrations.

Let’s understand the inner workings of a truck suspension system and make informed decisions regarding maintenance or upgrades.

The choice of suspension type depends on factors such as the intended use of the truck, load capacity, and desired ride quality. Here are some common types of truck suspensions:

Advantages:

Disadvantages:

Advantages:

Disadvantages:

Advantages:

Disadvantages:

Advantages:

Disadvantages:

Advantages:

Disadvantages:

Truck suspension is an integral part of any heavy-duty vehicle, responsible for supporting the weight of the truck, ensuring a smooth and comfortable ride, and maintaining stability and control.

Maintenance is a critical aspect of ensuring the longevity and performance of your truck's suspension system. Regular inspections, lubrication, and prompt replacement of worn or damaged parts are key to preserving the suspension's effectiveness.

It consists of tyres, tyre air, springs, shock absorbers, and linkage.

It consists of tyres, tyre air, springs, shock absorbers, and linkage.

The distance between the axle centre and the suspension mounting surface—the bottom of the trailer or slider box—defines the ride height of a suspension.

The distance between the axle centre and the suspension mounting surface—the bottom of the trailer or slider box—defines the ride height of a suspension.

Select a truck suspension by evaluating your load requirements, road conditions, and desired ride comfort.

Select a truck suspension by evaluating your load requirements, road conditions, and desired ride comfort.

Please try one more time!

Other Important Articles About Truck

Other Important Articles about Commercial Vehicle Insurance

Have queries related to Digit motor insurance policy? You can refer to our Policy Wordings for detailed information or reach out to our support team via WhatsApp self-support, email or phone using the information below:

Connect with our self-serve chat bot support - 7026061234

Write to us at hello@godigit.com

Contact

Call us on 1800-258-5956

Other Motor Insurance Plans and Guides

Currently there are no news to show.

Read More

Renew & Download Policy Document, Check Challan, Credit Score, PUC & more

Anytime, Anywhere. Only on Digit App!

4.7

Rated App56K+ Reviews

4.7

Rated App

56K+ Reviews

4.3

Rated App11K+ Reviews

4.3

Rated App

11K+ Reviews

Scan to Download

Author: Team Digit

Last updated: 07-04-2025

CIN: L66010PN2016PLC167410, IRDAI Reg. No. 158.

Go Digit General Insurance Limited | Corporate Office Address: Atlantis, 95, 4th B Cross Road, Koramangala Industrial Layout, 5th Block, Bengaluru 560095 | Registered Office Address: 1 to 6 floors, Ananta One (AR One), Pride Hotel Lane, Narveer Tanaji Wadi, Shivaji Nagar, Pune-411005, Maharashtra | Trade logo of Go Digit General Insurance Ltd. displayed above belongs to Go Digit lnfoworks Services Private Limited and is provided and used by Go Digit General Insurance Ltd. under license.

Explore exclusive features, file claims & access policy on Digit App!

You can also scan this QR code to download the App.