I agree to the Terms & Conditions

General

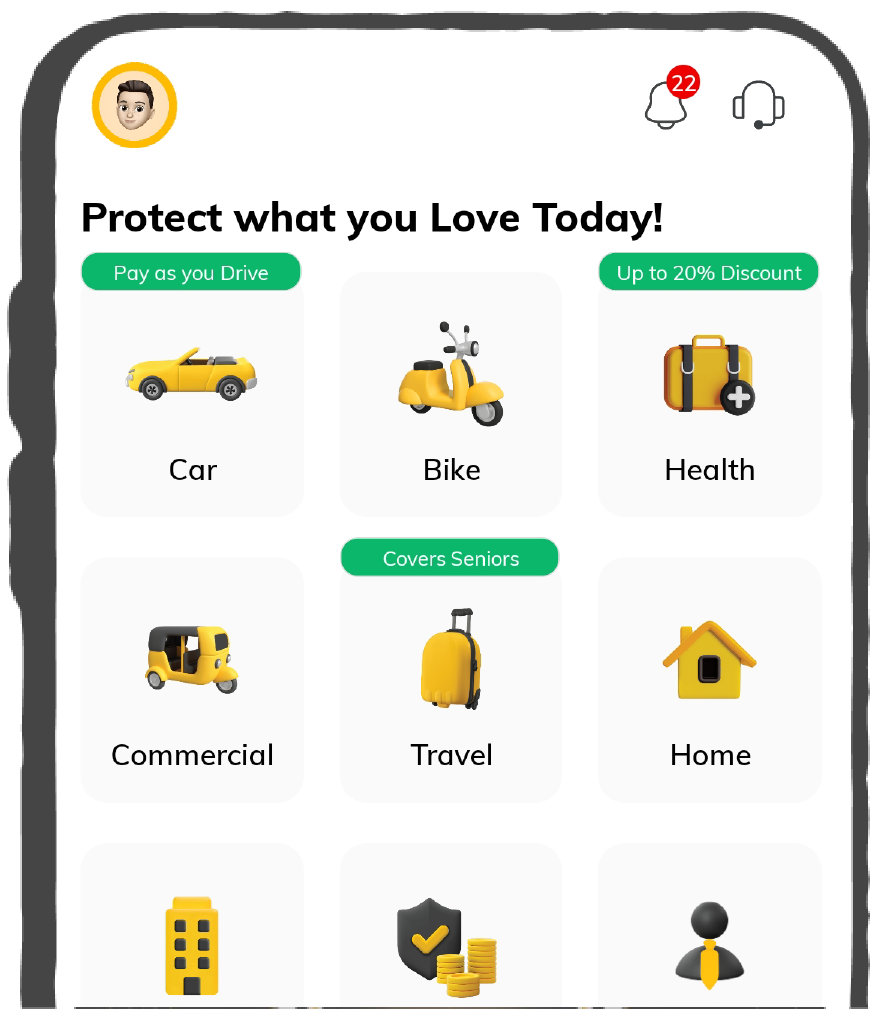

General Products

Simple & Transparent! Policies that match all your insurance needs.

37K+ Reviews

7K+ Reviews

Scan to download

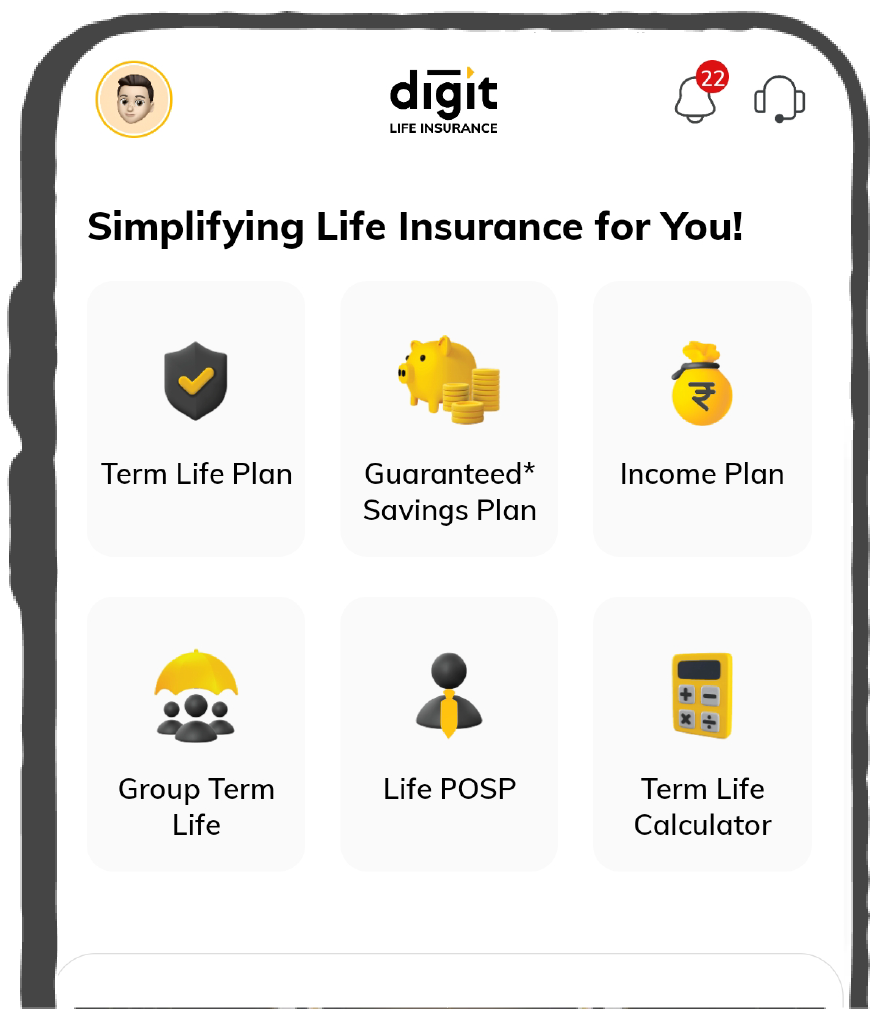

Life

Life Products

Digit Life is here! To help you save & secure your loved ones' future in the most simplified way.

37K+ Reviews

7K+ Reviews

Scan to download

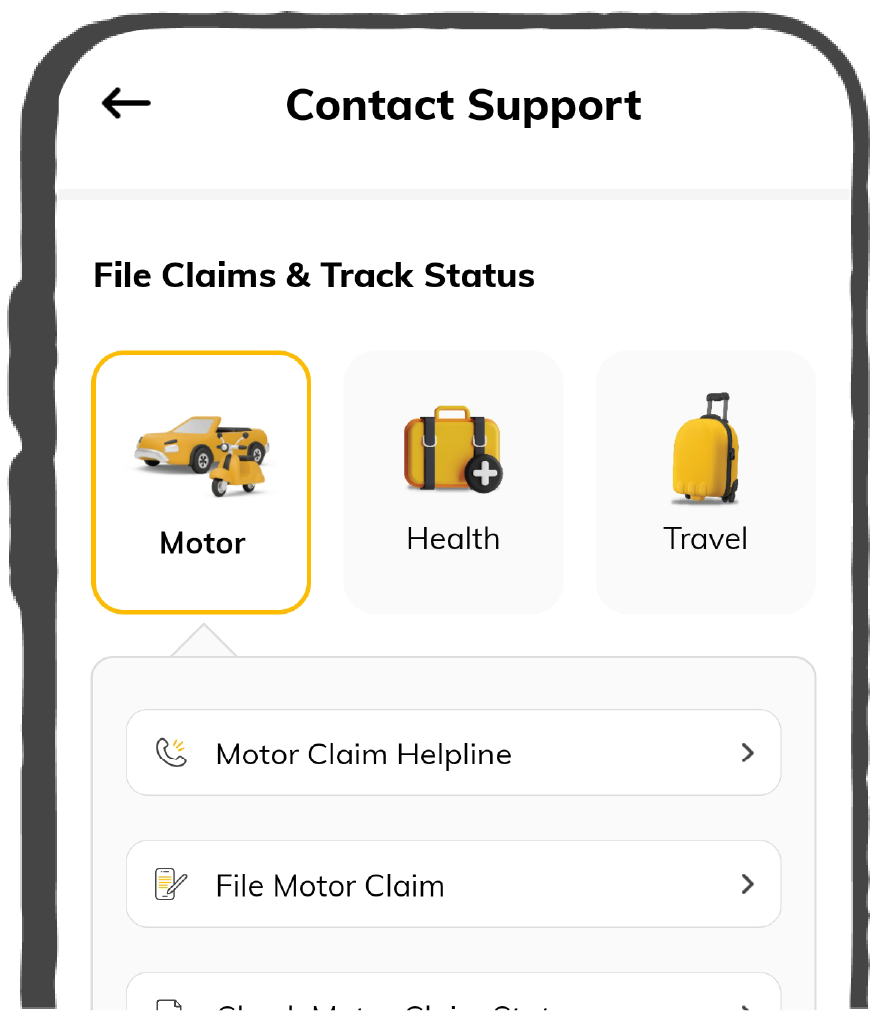

Claims

Claims

We'll be there! Whenever and however you'll need us.

37K+ Reviews

7K+ Reviews

Scan to download

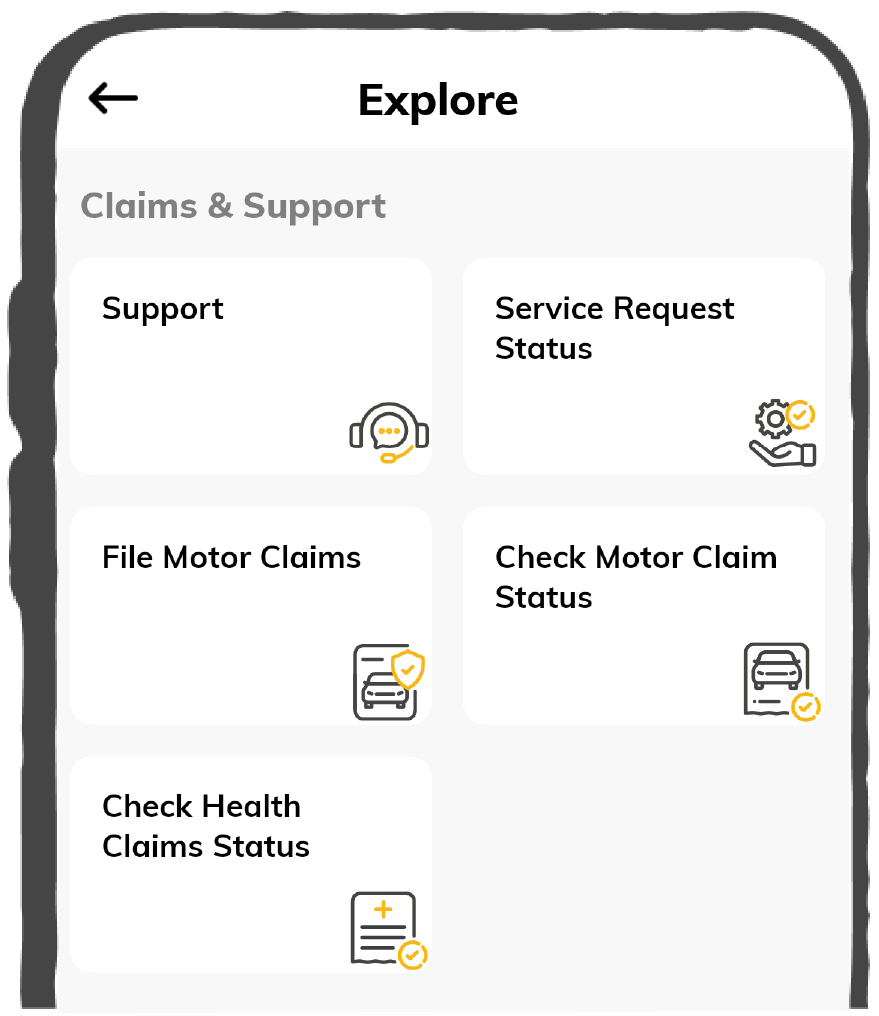

Resources

Resources

All the more reasons to feel the Digit simplicity in your life!

Tools & Calculators

Tools & Calculators

37K+ Reviews

7K+ Reviews

Scan to download

37K+ Reviews

7K+ Reviews

Logout

Logout

Our WhatsApp number cannot be used for calls. This is a chat only number.

2000+ Cashless

Network Garages

96% Claim

Settlement (FY23-24)

24*7 Claims

Support

I agree to the Terms & Conditions

Terms and conditions

Fork trucks, often referred to as forklift trucks or simply forklifts, are indispensable machines in the world of material handling and logistics. These powerful vehicles play a pivotal role in various industries, from warehouses and manufacturing plants to construction sites and distribution centres.

In this article, we will delve into the world of fork trucks, exploring their different types, features, benefits, safety regulations, and other details.

Fork trucks consist of a carriage with two fork-like prongs that can be raised and lowered to engage with pallets, crates, or other loads. These prongs are commonly referred to as "tines" or "forks."

Fork trucks are equipped with various power sources, including electric batteries, internal combustion engines, or even propane tanks, depending on the application and environment they are used.

Fork trucks come in a variety of types, each tailored to specific tasks and environments. Here are ten types:

Fork trucks offer a wide range of features and benefits that make them indispensable in various industries:

To ensure the safe operation of fork trucks, it's crucial to adhere to safety regulations and best practices. Here are some key safety considerations:

Therefore, fork trucks, or forklifts, are indispensable tools in modern industry, facilitating efficient material handling, increasing productivity, and improving workplace safety.

Understanding the various types, features, and safety regulations associated with forklifts is essential for anyone working in logistics, warehousing, manufacturing, or construction.

The three main parts of a forklift are the chassis or frame, the mast, and the forks or tines.

The three main parts of a forklift are the chassis or frame, the mast, and the forks or tines.

A 3-stage forklift refers to a forklift with a triple-stage mast, which has three sections that can be raised and lowered, providing greater lift height capability for stacking or reaching high shelves.

A 3-stage forklift refers to a forklift with a triple-stage mast, which has three sections that can be raised and lowered, providing greater lift height capability for stacking or reaching high shelves.

When the mast is lowered, a typical warehouse forklift stands between 85 and 90 inches tall, or seven to seven and a half feet.

When the mast is lowered, a typical warehouse forklift stands between 85 and 90 inches tall, or seven to seven and a half feet.

Forklifts are typically operated by certified forklift operators who have undergone training to safely drive and operate these industrial vehicles.

Forklifts are typically operated by certified forklift operators who have undergone training to safely drive and operate these industrial vehicles.

Please try one more time!

Other Important Articles About Truck

Other Important Articles about Commercial Vehicle Insurance

Have queries related to Digit motor insurance policy? You can refer to our Policy Wordings for detailed information or reach out to our support team via WhatsApp self-support, email or phone using the information below:

Connect with our self-serve chat bot support - 7026061234

Write to us at hello@godigit.com

Contact

Call us on 1800-258-5956

Other Motor Insurance Plans and Guides

Currently there are no news to show.

Read More

Renew & Download Policy Document, Check Challan, Credit Score, PUC & more

Anytime, Anywhere. Only on Digit App!

4.7

Rated App56K+ Reviews

4.7

Rated App

56K+ Reviews

4.3

Rated App11K+ Reviews

4.3

Rated App

11K+ Reviews

Scan to Download

Author: Team Digit

Last updated: 07-04-2025

CIN: L66010PN2016PLC167410, IRDAI Reg. No. 158.

Go Digit General Insurance Limited | Corporate Office Address: Atlantis, 95, 4th B Cross Road, Koramangala Industrial Layout, 5th Block, Bengaluru 560095 | Registered Office Address: 1 to 6 floors, Ananta One (AR One), Pride Hotel Lane, Narveer Tanaji Wadi, Shivaji Nagar, Pune-411005, Maharashtra | Trade logo of Go Digit General Insurance Ltd. displayed above belongs to Go Digit lnfoworks Services Private Limited and is provided and used by Go Digit General Insurance Ltd. under license.

Explore exclusive features, file claims & access policy on Digit App!

You can also scan this QR code to download the App.