What is Two-Stroke Engine in Bikes: Components, Application and Advantages

Most cars and trucks on the road use four-stroke reciprocating internal combustion engines. Two-stroke engines are another type typically found in lower-powered applications, such as lawn and garden equipment, mopeds, dirt bikes, small outboard motors, radio-controlled model planes, chainsaws, and jet skis.

What Is a Two-Stroke Engine?

A two-stroke engine is a type of internal combustion engine where a single power cycle is completed in a single crankshaft revolution. This is in contrast to a four-stroke engine, which requires two crankshaft revolutions to complete a power cycle.

The main difference between these two types of engines is the number of strokes required to complete a power cycle.

How Does Two Stroke Engines Work?

As the name suggests, two-stroke engines take two strokes or cycles to complete combustion. Here is the two-stroke engine working principle:

Step 1: Up Stroke or Suction & Compression Stroke

In a two-stroke engine, suction and compression strokes happen simultaneously. As the piston moves to the top dead centre (TDC) from the bottom dead centre (BDC), it opens the inlet port and creates a partial vacuum in the crankshaft.

This vacuum draws a mixture of fuel and air into the crankcase. At the same time, the piston compresses the mixture in the combustion chamber. The exhaust port remains closed during this stroke.

Step 2: Down Stroke or Power & Exhaust Stroke

The power stroke in a two-stroke engine is when the spark plug ignites the compressed mixture in the combustion chamber, creating a high-pressure force that moves the piston from TDC to BDC.

The inlet port remains open for the first half of the stroke, allowing a fresh mixture of fuel and air to be drawn into the crankcase. The exhaust port opens in the second half of the stroke, allowing the burnt gases to escape.

The transfer port also opens in the second half of the stroke, allowing the fresh mixture from the crankshaft to be pushed into the combustion chamber.

What Are the Components of Two Stroke Engine?

Components of a two-stroke engine work in conjunction to make the whole process work. Here are the two-stroke engine parts:

1. Crankshaft

It changes the back-and-forth movement into a circular motion.

2. Piston

3. Spark Plug

Supplying electrical current to the combustion chamber initiates the ignition of the air-fuel mixture, resulting in the rapid expansion of gases.

4. Flywheel

Flywheel functions as a mechanical apparatus for storing energy.

5. Connecting Rod

It transmits motion from piston to crankshaft while functioning as a lever arm.

6. Counter Weight

The counterweight installed on the crankshaft mitigates vibrations caused by imbalances in the rotating assembly.

7. Inlet & Outlet Ports

These openings enable the inflow and outflow of fresh air and fuel mixture in and out of the cylinder.

How do Internal Combustion (IC) Engines work?

Internal combustion engines work on the principle that when a fuel air mixture is ignited, it generates gases that expand rapidly. This expansion is used to drive a piston within the confined space of the engine.

The piston drives the crankshaft, which causes rotational motion. This rotational motion is transferred to the wheels, allowing the vehicle to move.

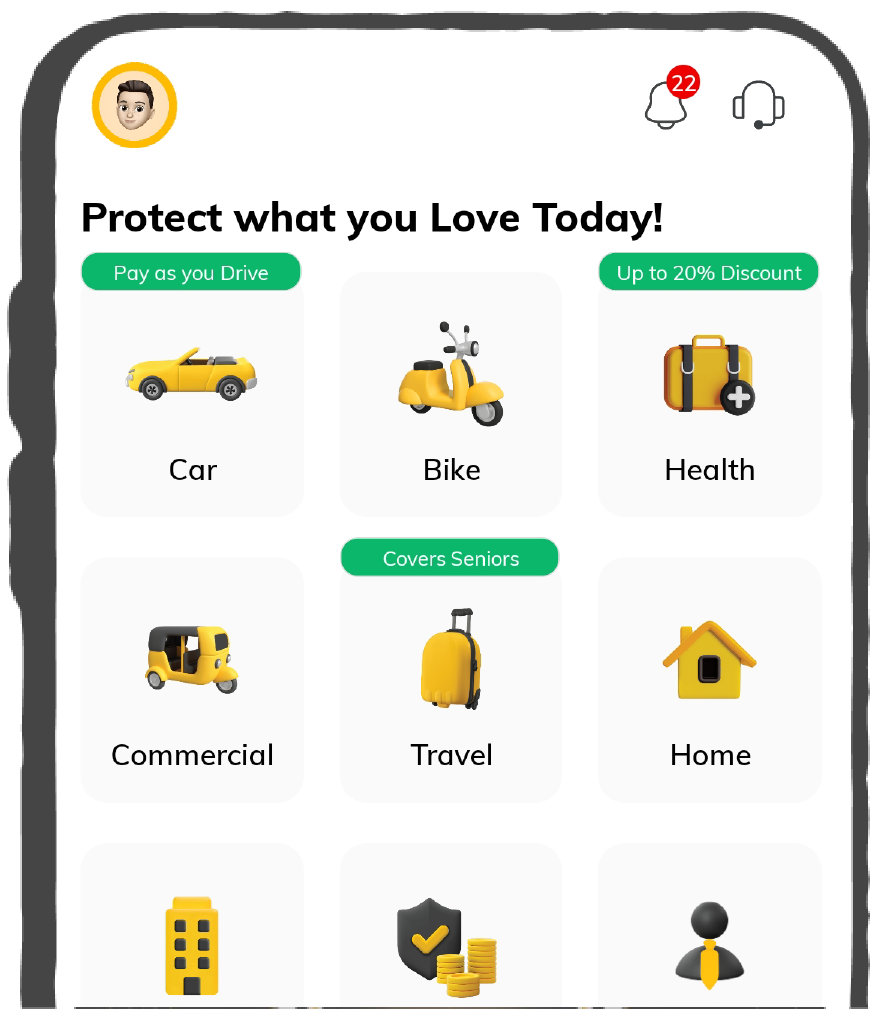

What Are the Applications of Two Stoke Engines?

As a result of stricter air pollution regulations, the utilisation of two-stroke engines has diminished; however, they continue to be used in numerous low-power applications, including:

High-performance, small-capacity motorcycles, mopeds

Dirt bikes

Outboard motors

Underbones, tuk-tuks, scooters, snowmobiles, go-karts, etc.

Model aeroplanes, Ultralight aeroplanes

Outdoor power tools such as chainsaws, lawnmowers, and weed-whackers

Electric generator, pump, etc.

Two-stroke diesel engines for ship propulsion

What Are the Advantages of Two Stroke Engine?

Here are the advantages of a two-stroke engine:

Two-stroke engines have a high power-to-weight ratio.

A lighter flywheel is needed due to a more evenly distributed turning force.

The power generated is twice as much in two-stroke engines compared to four-stroke engines with the same dimensions.

Two-stroke engines take up less space while delivering the same power output.

The construction and operation of a two-stroke engine are straightforward.

Two-stroke engines are lighter than four-stroke engines with the same power output.

Energy consumption during the exhaust and suction strokes is reduced.

It requires less maintenance.

What Are the Disadvantages of Two Stroke Engine?

Now that you know the advantages of a two-stroke engine, you should also be aware of its disadvantages:

When a two-stroke engine operates on the Otto cycle, a significant amount of fresh charge is lost due to inadequate volumetric efficiency.

There is a higher consumption of lubricating oil in two-stroke engines.

The presence of intake and exhaust ports in a two-stroke engine limits the effectiveness of compression.

Reduced volumetric efficiency is a factor that decreases the efficiency of high-speed two-stroke engines.

At high loads, two-stroke engines experience a lack of smooth operation due to charge dilution.

Why Are Two-Stroke Engines Less Efficient Than Four-Stroke Engines?

The efficiency of a two-stroke or a four-stroke engine depends on what type of vehicle you are using.

The two-stroke engine offers a rapid cycle, delivering substantial power without adding excessive bulk. This makes it well-suited for high-performance off-road vehicles and lightweight lawn tools, where a lower power-to-weight ratio is desirable.

On the other hand, four-stroke engines excel in applications involving multi-cylinder engines like cars, trucks, SUVs, and larger vehicles. Due to their unfavourable emissions profile, two-stroke engines are no longer commonly used in automobiles.

Moreover, four-stroke engines offer enhanced reliability and are easier to manage and control.

Now that you know what is a two-stroke engine, you should also know that it causes a lot of pollution. They leak oil, which causes a visible film or sheen around them. This makes them unsuitable for most applications, but they are still used in some cases where a high power-to-weight ratio is critical.

Continue with

Continue with